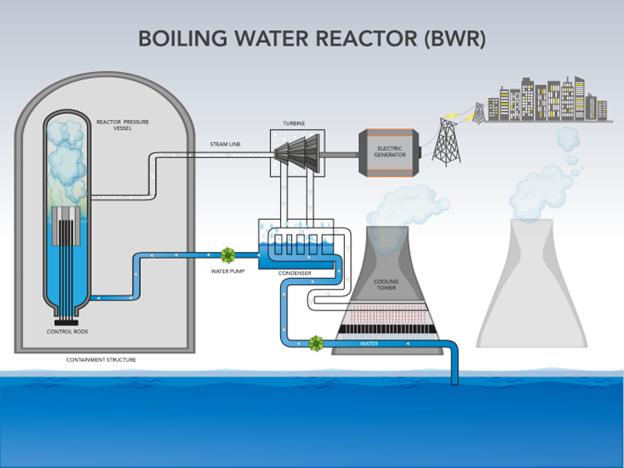

Boiling is a very powerful type of Heat Transfer CFD Simulation where a liquid changes into a gas, like when water turns into steam. This process is very important for many industries. For example, boiling heat transfer is essential for the design and safety of equipment like nuclear reactors, large heat exchangers, and steam generators. Understanding how boiling works helps engineers make these systems safer and more efficient.

Contents

ToggleThe process of boiling is complex because of how bubbles form and move. This makes it difficult to study with simple experiments. This is why boiling CFD simulation is so important. Using powerful software like ANSYS Fluent, engineers can create a virtual model to see exactly how the boiling happens. A boiling simulation in ANSYS Fluent allows us to predict important factors and design parameters. This helps improve the performance of industrial equipment. At CFDLAND, we have great experience with these types of simulations. You can explore our expert Heat Transfer CFD Simulations Tutorial.

Figure 1: Boiling heat transfer is vital for many industrial applications, including the safe design of nuclear reactors and large-scale heat exchangers, often analyzed with CFD simulation.

Understanding Boiling Physics for CFD

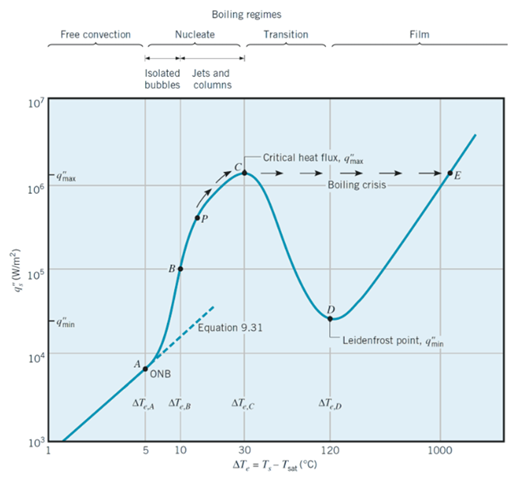

To create an accurate boiling CFD simulation, we must first understand the physics. The way a liquid boils changes dramatically depending on how hot the heating surface is. Scientists show this relationship using a famous graph called the “boiling curve.” This curve is essential for understanding boiling heat transfer. It shows how much heat is transferred from the surface to the liquid at different surface temperatures. The key parameter on this curve is the “excess temperature,” also called wall superheat. This is simply the difference between the hot wall’s temperature and the liquid’s saturation (boiling) temperature.

Figure 2: Typical boiling curve for water at 1 atm. Adopted from “Fundamentals of Heat and Mass Transfer” by THEODORE L. BERGMAN et al.

The boiling curve shows four main boiling regimes. First is Free Convection, where the wall is warm but not hot enough to create bubbles. The heat transfers just like in a normal heated liquid. The second and most important regime is Nucleate Boiling. This is where bubbles start to form on the surface, which is why it’s the most efficient region for heat transfer. The bubbles mix the liquid very well, causing the boiling heat transfer coefficient to become very high. Most industrial equipment is designed to operate in this regime.

As the wall gets even hotter, we reach a peak on the curve. This peak is called the Critical Heat Flux (CHF). This is the maximum possible heat transfer we can get from nucleate boiling. The CHF is a critical safety limit in many applications, especially in the nuclear industry. Going beyond this point can cause a sudden and dangerous rise in temperature. The next regime is Transition Boiling, an unstable region where the heat transfer actually decreases as the temperature rises. This happens because too many bubbles cover the hot surface, acting like an insulating blanket. Finally, we reach Film Boiling. Here, the surface is so hot that it is completely covered by a layer of vapor. This is also called the Leidenfrost effect. Because vapor does not conduct heat well, the heat transfer rate is much lower. Understanding these different regimes is the first step to choosing the correct boiling model in ANSYS Fluent.

ANSYS Fluent Boiling Models

When you need to perform a boiling simulation in ANSYS Fluent, the most powerful and widely used tool is the RPI Wall Boiling Model. This advanced model was developed at Rensselaer Polytechnic Institute (RPI) to accurately predict nucleate boiling. It is a very comprehensive model, perfect for detailed engineering analysis. You can see a practical example of its application in our tutorial on Nucleate Boiling CFD Simulation with the RPI Model. The main idea of this model is called Heat Flux Partitioning. Instead of treating the heat from the wall as one single value, the model splits it into three different parts.

The total heat flux from the wall (q_wall) is divided into:

- The Evaporative Heat Flux (qE): This is the energy that is used to create and grow the vapor bubbles on the hot surface.

- The Quenching Heat Flux (qQ): This represents the heat transfer that happens when a bubble detaches from the surface and colder liquid rushes in to “quench” or cool that spot for a moment.

- The Convective Heat Flux (qC): This is the standard single-phase convection that happens on the parts of the wall where there are no bubbles.

Figure 3: A diagram of the heat flux partitioning concept used in the RPI boiling model in ANSYS Fluent. The total wall heat flux is divided into convective, quenching, and evaporative components for an accurate boiling simulation.

By dividing the heat in this way, the RPI model gives a much more realistic simulation of the boiling process. Besides heat flux partitioning, the model also has important sub-models for Bubble Dynamics. This includes important parameters like the bubble departure diameter (how big bubbles get before they leave the surface), the frequency of bubble departure (how often they leave), and the nucleation site density (how many points on the surface can create bubbles). These settings are crucial for a correct simulation. For a different approach focused on the detailed growth of a single bubble, engineers sometimes use the VOF (Volume of Fluid) method. This technique is excellent for studying the physics of an isolated bubble in nucleate boiling by precisely tracking the interface between the liquid and vapor.

Figure 4: A VOF CFD simulation showing the detailed growth of an isolated bubble during nucleate boiling. This ANSYS Fluent method is excellent for studying the fundamental physics of bubble dynamics.

Setting Up a Boiling Simulation in ANSYS Fluent

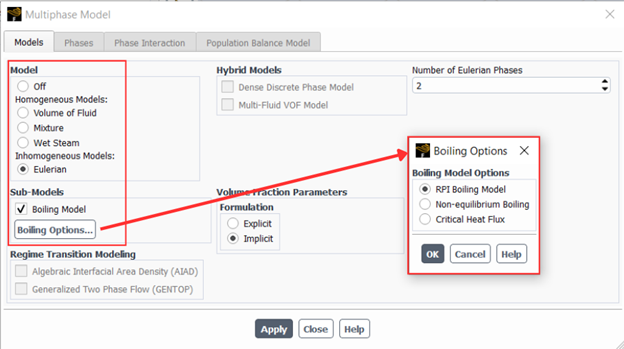

Setting up a boiling CFD simulation in ANSYS Fluent requires careful steps. Because boiling involves both liquid and vapor, we must first activate a multiphase model. The most common and powerful choice for this is the Eulerian multiphase model. This model allows Fluent to solve separate equations for the liquid phase and the vapor phase, which is essential for an accurate boiling simulation.

Once the Eulerian model is active, you can enable the boiling models. Inside the Boiling options, you will find the options for Wall Boiling. Here, you must select the RPI Wall Boiling model. Next, you need to define the boundary conditions. For a typical flow boiling case, you will set a mass flux or velocity at the inlet with a specific liquid temperature (often subcooled). For the heating wall, you will usually specify a constant wall heat flux or a fixed temperature that is above the saturation temperature.

Figure 5: The Wall Boiling model setup panel in ANSYS Fluent. Here, users can activate the RPI model and define key parameters for the CFD simulation.

The solver settings are also very important for a stable and accurate solution. It is highly recommended to use the Coupled solver with the Pseudo Time Stepping method. This setup helps the complex equations to converge properly. Getting a good result also depends on validation. Engineers often compare their simulation results against classic validation experiments, such as those by Bartolomei et al. or Pierre and Bankoff, to ensure their model setup is correct.

While the RPI model is excellent for simulating overall boiling behavior, sometimes it is useful to study the detailed physics of a single bubble. For this, a different approach using the VOF model is needed. At CFDLAND, we have also explored this in our tutorial on Isolated Bubble CFD Simulation in Nucleate Boiling, which focuses on the growth and departure of one bubble.

Conclusion

In this guide, we have explored the essential concepts of boiling heat transfer and how to model it using Computational Fluid Dynamics. We learned that understanding the boiling curve is the first step to analyzing any boiling system, from the highly efficient nucleate boiling regime to the critical safety limit of Critical Heat Flux (CHF). We also saw that ANSYS Fluent provides powerful tools like the RPI wall boiling model, which uses the principle of heat flux partitioning to accurately simulate these complex phenomena.

As shown in validation studies, boiling CFD simulation results can show good agreement with experimental data, making CFD an essential tool for designing and ensuring the safety of industrial equipment like nuclear reactors and heat exchangers. However, setting up an accurate simulation is a challenging task. The results are very sensitive to the sub-models chosen for bubble dynamics, such as bubble departure diameter and frequency.

CFD simulation of boiling heat transfer is difficult and takes a lot of time. Don’t worry, we are ready to help you. Our CFD experts have been doing simulations with ANSYS Fluent for years and have completed many projects. If you need professional assistance, you can Order your ANSYS Fluent CFD simulation projects from CFDLAND and be sure of the quality of the work.