ANSYS Heat Sink Simulation: Thermal Performance CFD Analysis with ANSYS Fluent

ANSYS Heat Sink Simulation: Thermal Performance CFD Analysis with ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€170 Original price was: €170.€150Current price is: €150.

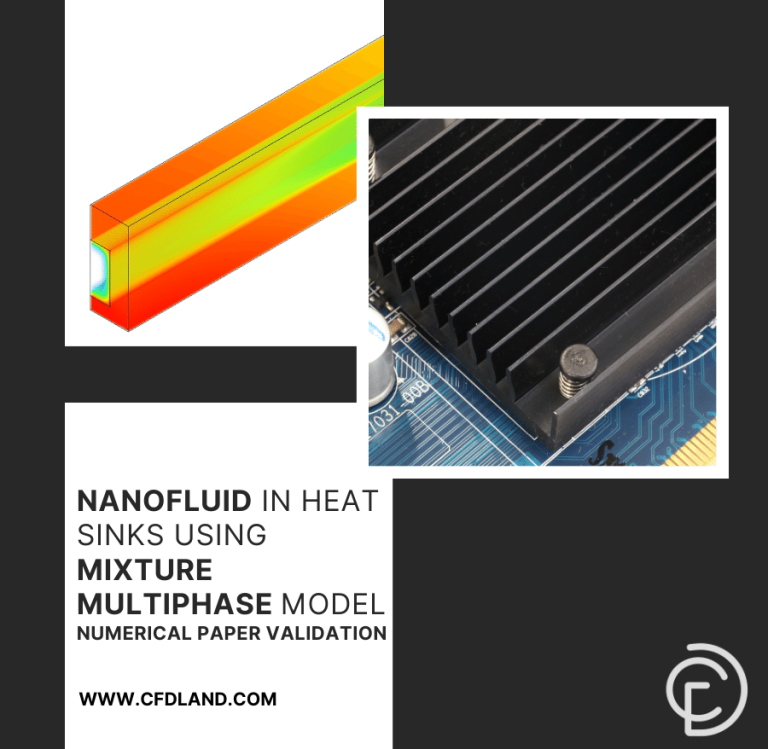

ANSYS Heat Sink Simulation analysis is essential for keeping modern electronics cool and reliable. High-power components like CPUs and GPUs generate a lot of heat, and if this heat is not removed, they can overheat and fail. A heat sink is a metal component with many fins designed to pull this heat away. To ensure a heat sink works perfectly before it is built, engineers use powerful software like ANSYS Fluent. This process, often called a Heat Sink CFD study, allows us to create a digital twin of the heat sink.

By running an ANSYS Heat Sink Simulation, we can see exactly how heat travels from the hot electronic chip into the metal fins, and then into the surrounding air. This simulation of “conjugate heat transfer”—heat moving through both solids and fluids—is a powerful tool. It allows engineers to test different shapes, materials, and fan speeds on the computer, saving time and money. This report details a Heat Sink Simulation Fluent analysis for an industrial heat sink to verify its cooling performance under a specific heat load. For those interested in learning more about the principles of thermal modeling, our detailed heat transfer tutorials are available at: https://cfland.com/product-category/engineering/heat-transfer-cfd-simulation/

Figure 1: A schematic showing the geometry of the industrial heat sink used for the Heat Sink CFD analysis

Simulation process: Fluent Setup for Conjugate Heat Transfer Simulation

The simulation process for this Heat Sink Simulation CFD project began by creating a precise digital model of the industrial heat sink. To get accurate results, a very high-quality mesh was needed. Using ANSYS ICEM CFD, a specialized tool for grid generation, a fully structured mesh containing 4,952,619 cells was created. This large number of organized cells is critical for correctly calculating the speed and temperature of the air as it flows through the narrow channels between the heat sink fins. A poor mesh would give wrong results.

Inside the ANSYS Fluent software, the physics of the problem were defined to match real-world conditions. This is a “conjugate heat transfer” problem because we must solve for heat moving through the solid metal and the moving fluid (air) at the same time. The heat sink material was set to Aluminum because it is good at conducting heat. The boundary conditions were then set up. Air was defined to enter the domain at a standard room temperature of 298.15 K. To represent the heat from a working electronic chip, a constant heat flux of 70,222 W/m² was applied to the base of the heat sink. This complete and careful setup allows Fluent to accurately predict the final temperatures of both the heat sink and the air.

Figure 2: The high-quality all-structured mesh with 4,952,619 cells generated in ANSYS ICEM

Post-processing: Thermal Performance and Cooling Efficiency Analysis

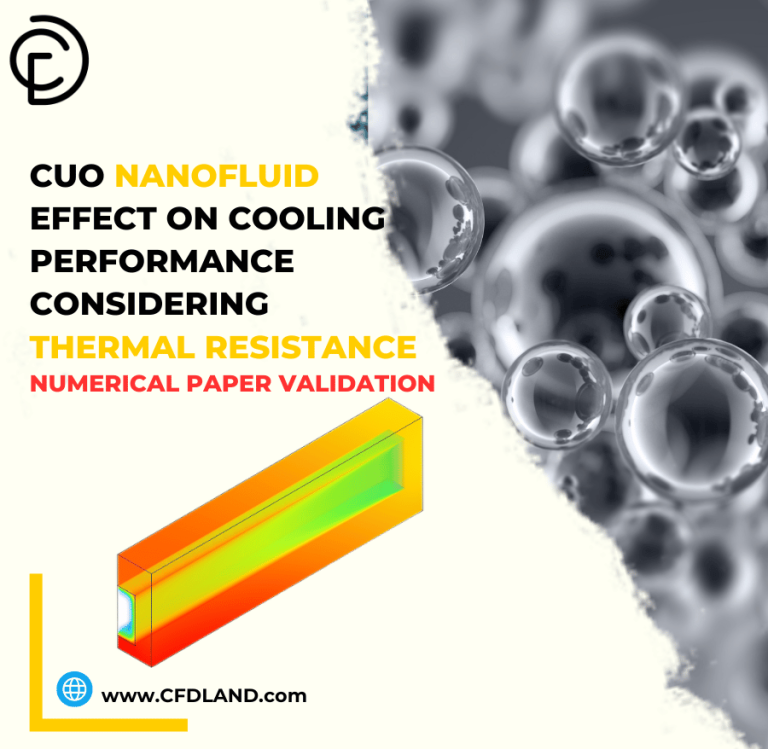

The results of this Ansys Heat Sink Simulation provide a clear verification of the design’s thermal performance. First, by examining the temperature on the solid aluminum heat sink (Figure 5), we can see that the heat is properly managed. The base of the heat sink, where the electronic components are mounted, reaches a maximum temperature of approximately 346 K. The heat then effectively spreads from this hot central area up into the cooler fins, which are shown in green and blue. This temperature map is the first critical result for a designer, as it confirms that the component’s operating temperature stays within safe limits.

The most important engineering analysis comes from studying how the air heats up, which is visualized in the new contour in Figure 4. This contour shows a vertical slice of the air domain. The air enters from the left at a cool 298 K (dark blue). As it flows over the hot electronic components on the floor, it immediately begins to absorb heat, creating distinct thermal plumes shown in red and orange. The legend confirms that the hottest air pockets reach the same temperature as the heat sink base, 346 K. This contour proves that the heat is successfully being transferred from the solid surfaces into the fluid. The final, and most crucial, piece of data is the average outlet temperature of the air, which the Heat Sink CFD simulation calculated to be 315.52K.

Figure 3: An isometric temperature view of the industrial heat sink with electronic components and cooling fans.

Figure 4: A temperature contour on a vertical plane through the air domain.

Figure 5: Temperature contours on the solid aluminum heat sink, illustrating how heat spreads from the hot base into the cooler fins.

For a manufacturer, this precise outlet temperature is the key performance indicator. The difference between the inlet and outlet temperatures (315.52 K – 298.15 K) is 17.37 K. This 17.37 K temperature rise is the most important achievement of this simulation. It is a direct measurement of how much energy the heat sink removed from the system. An engineer can now confidently use this validated Heat Sink Ansys model to test improvements. For example, they can virtually change the fan speed or the fin spacing and see exactly how it affects the outlet temperature, all without building a single piece of hardware. This saves enormous amounts of time and money in the product development process.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€160 Original price was: €160.€80Current price is: €80.

€265 Original price was: €265.€135Current price is: €135.

€360 Original price was: €360.€185Current price is: €185.

€360 Original price was: €360.€185Current price is: €185.

€360 Original price was: €360.€180Current price is: €180.

€245 Original price was: €245.€185Current price is: €185.

Reviews

There are no reviews yet.