Compressible Flow in Nozzle: A Fluent CFD Training Guide

Compressible Flow in Nozzle: A Fluent CFD Training Guide

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

Free

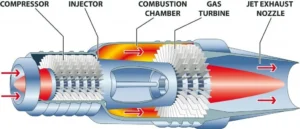

Compressible flow in a nozzle is a very important topic for building rockets and jet engines. When a gas like air moves very fast, it can be squeezed, or compressed. This is very different from water in a pipe. A Compressible Flow In Nozzle CFD simulation helps engineers see what happens inside special nozzles called converging-diverging or De Laval nozzles. These special tubes are key to creating supersonic flow, where the gas moves faster than the speed of sound. A Compressible Flow In Nozzle Fluent analysis lets us study the Mach number, which tells us how fast the gas is moving. Understanding this Nozzle CFD analysis is essential for designing powerful and efficient propulsion systems. This study is based on a classic aerospace engineering problem [1].

Figure 1: A schematic of the converging-diverging nozzle, a key application in aerospace engineering CFD [1].

Simulation Process: Fluent Setup, Axisymmetric Model for Ideal Gas Flow

To make the simulation efficient, we used a 2D axisymmetric model. This is a smart way to solve a 3D problem by looking at just one slice of the nozzle. We created a high-quality structured grid with 13,530 cells. In ANSYS Fluent, we told the computer that the fluid is an ideal gas. This is the correct physics model to use for air in this type of Nozzle Fluent simulation because it accurately describes how the air’s density will change as its pressure and temperature change. This careful setup allows us to precisely capture the physics of supersonic flow.

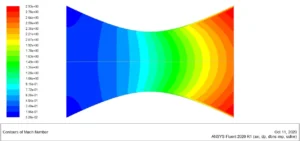

Figure 1: The structured grid on the 2D axisymmetric model for the Nozzle CFD simulation.

Post-processing: CFD Analysis, Visualizing Supersonic Acceleration and Cooling

The Mach number contour provides a professional visual of the air breaking the sound barrier. The professional contour shows that air enters the nozzle from the left moving slowly, with a Mach number of only 0.05. As the nozzle gets narrower, the air speeds up. It reaches exactly the speed of sound, Mach 1.0, at the narrowest point, which is called the throat. This is a very important condition known as choked flow. After the throat, the nozzle opens up, and the air continues to accelerate to an amazing Mach 2.93 at the exit. This smooth acceleration is exactly what engineers want to see for a high-performance rocket nozzle.

Figure 3: Mach number distribution from the Compressible Flow In Nozzle CFD analysis, showing the acceleration from subsonic to supersonic flow.

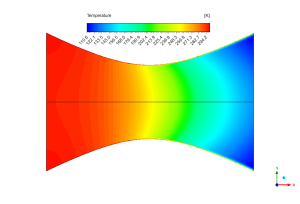

The temperature contour tells the other half of the story. This professional visual shows that the air starts at a normal room temperature of 300 Kelvin at the inlet. As the air speeds up, it expands and uses its heat energy to gain speed. This causes the air to get very cold. At the nozzle exit, the temperature drops to just 111 Kelvin, which is a huge temperature drop of 189 Kelvin. This cooling effect, known as expansion cooling, is a direct result of the compressible flow physics. The most important achievement of this simulation is the perfect validation of fundamental gas dynamics theory, showing exactly how a converging-diverging nozzle converts thermal energy into kinetic energy to produce stable, shock-free supersonic flow, which is the core principle behind all modern rocket propulsion.

Figure 4: Static temperature distribution from the Compressible Flow In Nozzle Fluent simulation, showing the significant cooling due to expansion.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€330 Original price was: €330.€175Current price is: €175.

€145 Original price was: €145.€115Current price is: €115.

€140 Original price was: €140.€125Current price is: €125.

€255 Original price was: €255.€135Current price is: €135.

€240 Original price was: €240.€135Current price is: €135.

€185 Original price was: €185.€145Current price is: €145.

Reviews

There are no reviews yet.