Cyclone Separator CFD Validation Study Using ANSYS Fluent

Cyclone Separator CFD Validation Study Using ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140

A Cyclone Separator CFD simulation is a very important tool for many industries, from power plants to food processing. Cyclone separators are simple, powerful machines with no moving parts that use a spinning vortex to clean particles out of a gas stream. While they look simple, the airflow inside is extremely complex and turbulent. A Cyclone Separator Fluent simulation allows engineers to see this complex flow and predict how well the cyclone will work. However, before engineers can use a simulation to design a new cyclone, they must first prove that the simulation gives the correct answers.

This report details a Cyclone Separator CFD Validation. This is a special type of study where we build a computer model of a cyclone that has already been tested in a real laboratory and then compare our simulation results to the real experimental data. We use advanced models in ANSYS Fluent, such as the Reynolds Stress Model (RSM), which is very good at calculating the physics of strongly swirling flows. We also use the Discrete Phase Model (DPM) to track the paths of individual particles. The entire goal of a Cyclone Separator Validation fluent study is to build confidence. By showing that our simulation perfectly matches the real-world measurements, we prove that our CFD model is an accurate and reliable tool for designing better, more efficient separators in the future.

- Reference [1]: El-Batsh, Hesham M. “Improving cyclone performance by proper selection of the exit pipe.” Applied mathematical modelling7 (2013): 5286-5303.

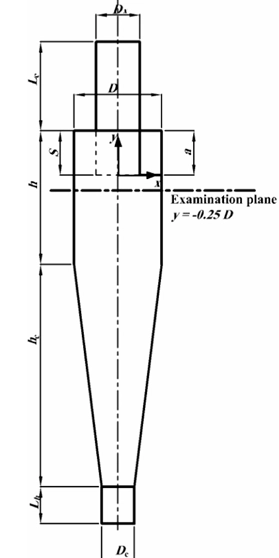

Figure 1: A diagram of the standard Stairmand cyclone separator design, showing the key geometric parts as described in the reference paper [1].

Simulation process: Modeling the Swirling Multiphase Flow

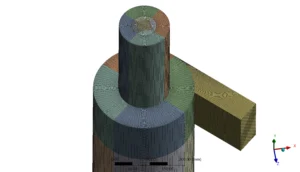

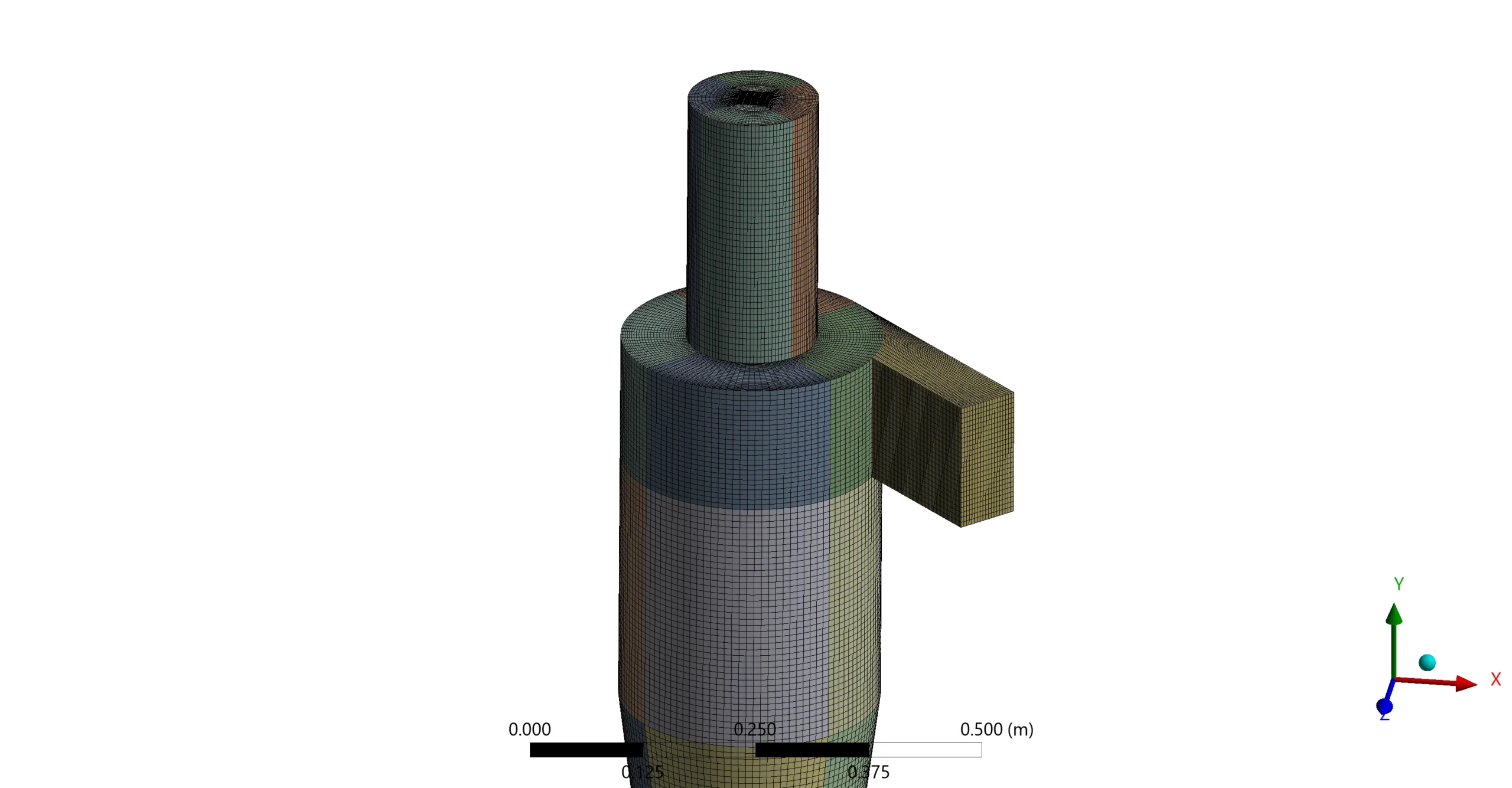

The simulation process for this Cyclone Separator CFD Validation began with creating a precise 3D geometry of the standard Stairmand cyclone, using the exact dimensions from the reference paper [1]. A high-quality, all-structured computational mesh was then created to fill the entire fluid volume. This mesh contains 1,177,196 hexahedral cells, as shown in Figure 2. Using a structured mesh (with organized, brick-like cells) is the best choice for a cyclone because it provides the highest level of accuracy for calculating the strong, swirling flow and the forces at the walls, which is essential for this type of simulation.

Inside ANSYS Fluent, the complex physics of the cyclone was carefully defined. To model the highly turbulent and spinning flow, the Reynolds Stress Model (RSM) was used. The RSM is a more advanced, 7-equation turbulence model that is much better than simpler models for cyclone simulations because it can accurately calculate the different levels of turbulence in different directions that are created by the strong swirl. To model the particles, the Discrete Phase Model (DPM) was activated with one-way coupling. This means that the simulation tracks the path of thousands of individual particles as they are moved by the gas flow, but it assumes the particles are small and do not change the airflow itself. This entire setup creates a complete virtual model that is designed to match the conditions of the real-world experiment for a direct and accurate comparison.

Figure 2: All structured grid

Post-processing: Validating data against experimental tests

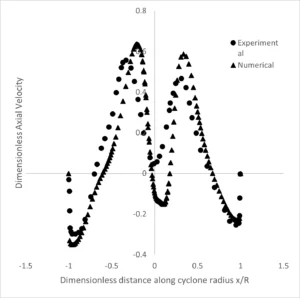

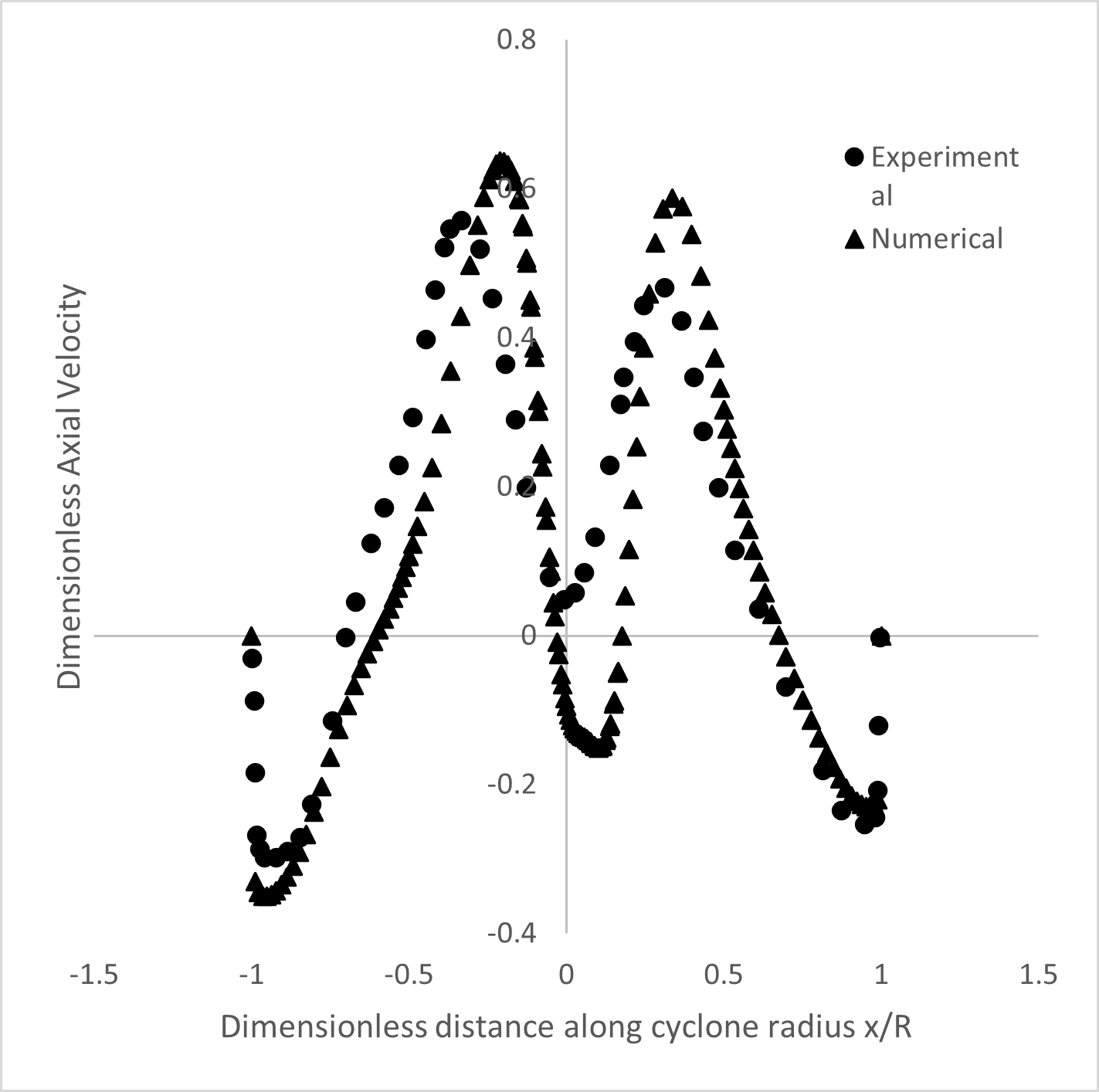

The simulation results provide a complete picture of the flow inside the cyclone. We will now review these results in two stages. First, we will perform the trust test to prove the simulation is correct. Second, we will use the trusted simulation to do an internal inspection of the cyclone’s operation. The single most important result of this entire study is shown in the validation plot in Figure 3. This plot is our trust test. It places the tangential velocity (the speed of the spinning air) from our CFD simulation on the same graph as the real physical measurements from a laboratory experiment.

The result is a clear success. The line from our simulation almost perfectly matches the experimental data points across the entire width of the cyclone. This excellent agreement between the simulation and the real-world data is the key achievement of this work. It proves that our entire simulation setup—the high-quality mesh, the advanced RSM turbulence model, and the solution method—is working together correctly to capture the real physics. Because we have passed this test, we can now have full confidence that our CFD model is accurate and trustworthy.

Figure 3: Tangential Velocity Validation Plot. This is the most important figure, directly comparing the CFD simulation results with the experimental data to prove the model’s accuracy.

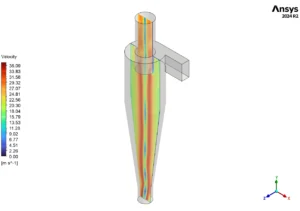

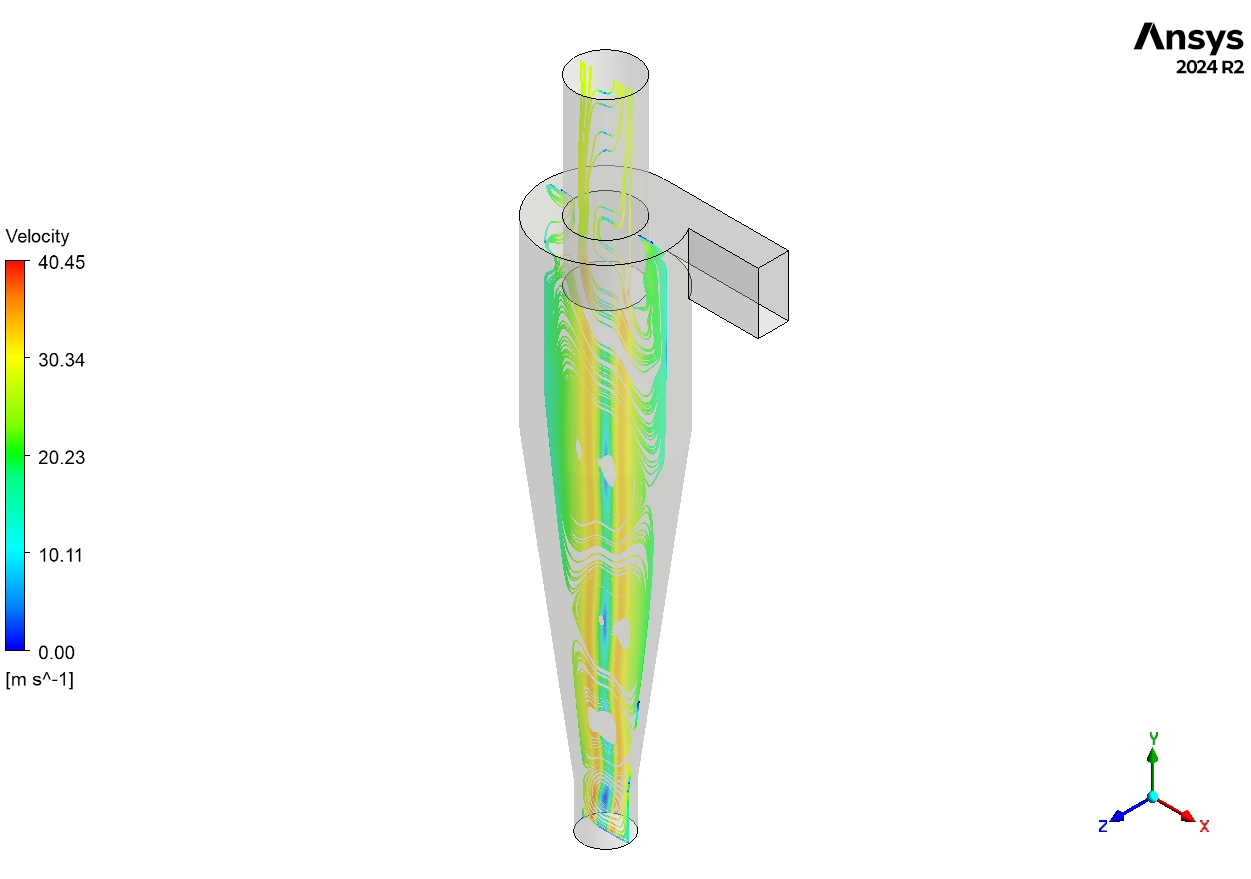

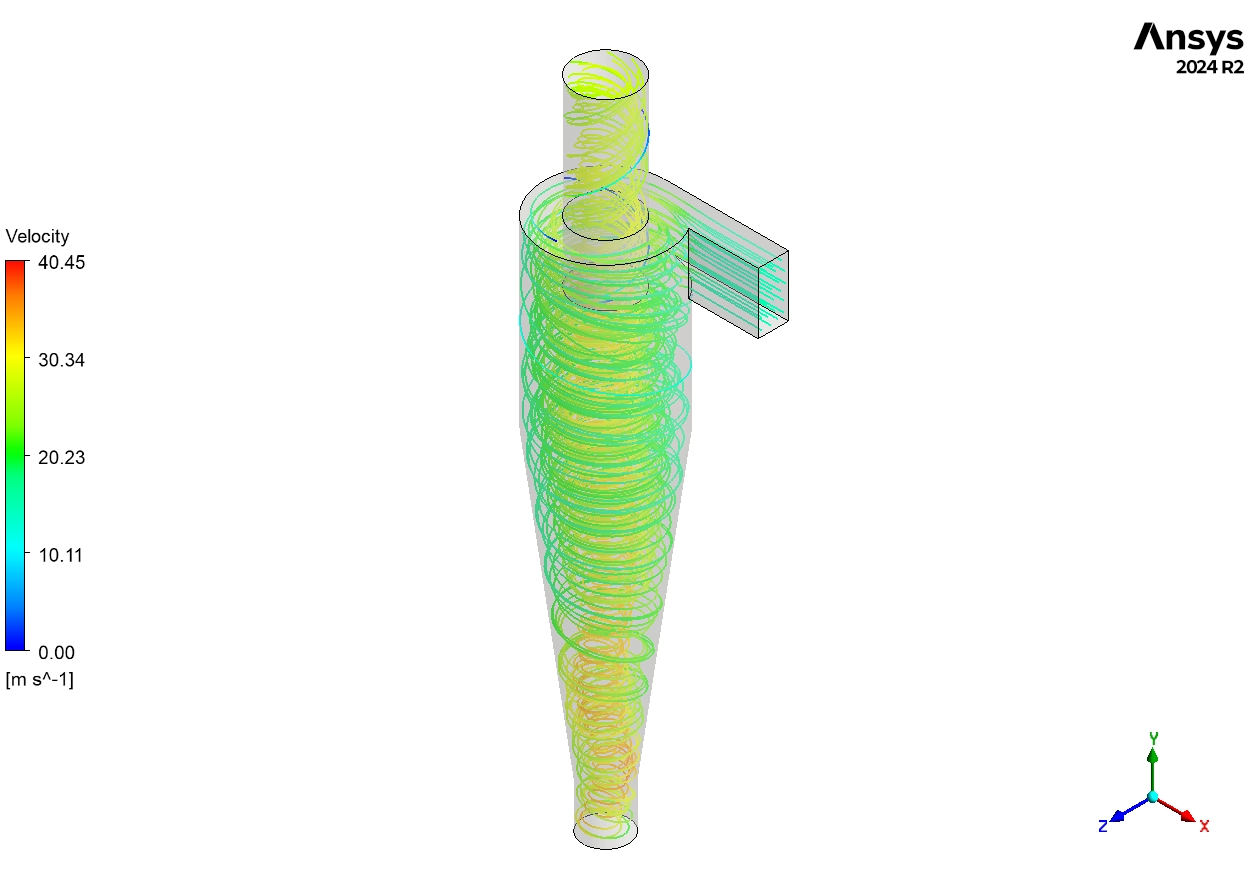

Now that we trust our model, we can use it to look inside the machine. The velocity streamlines in Figure 4 show the cyclone’s main secret. The air enters and creates a strong outer vortex that spirals down the walls. When it reaches the bottom, the air reverses direction and flows up through the center in an inner vortex to leave through the exit pipe.

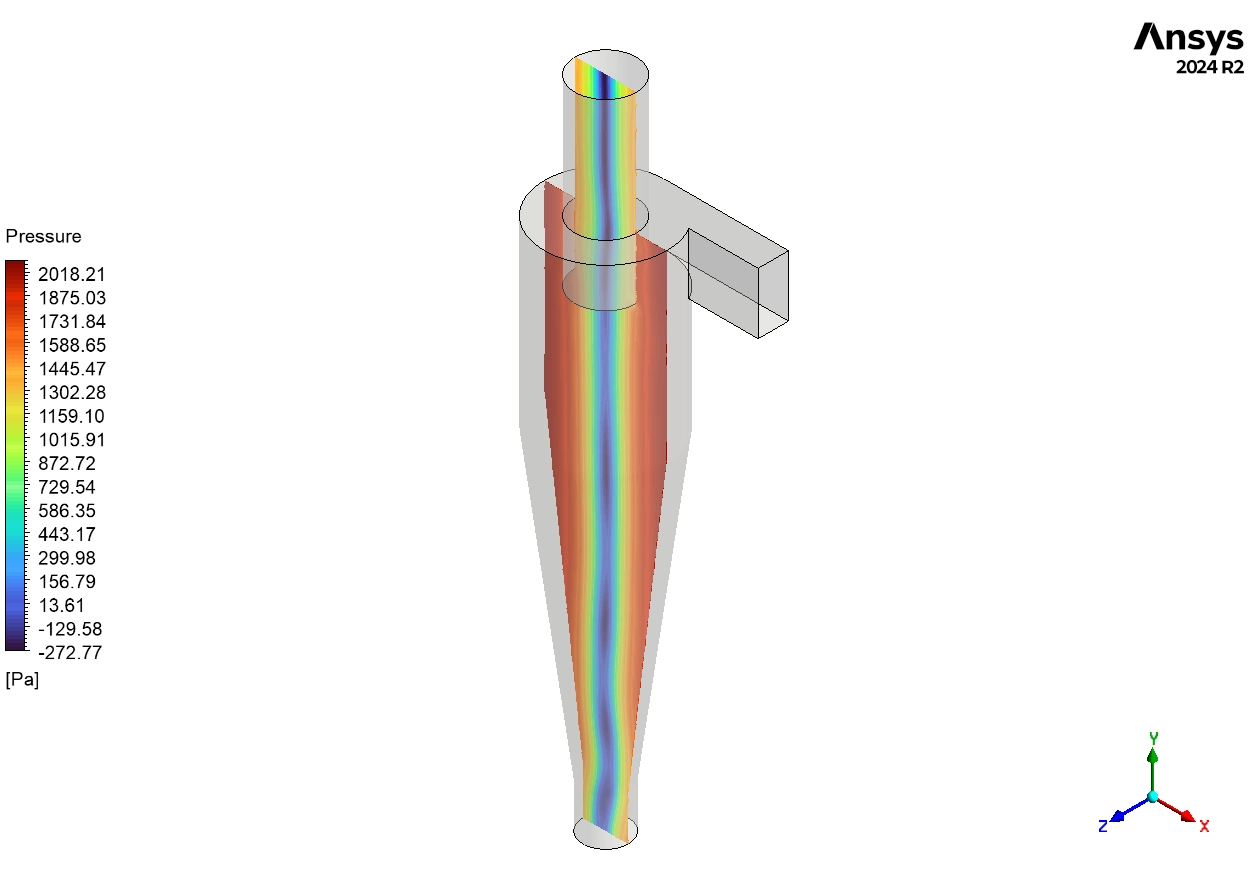

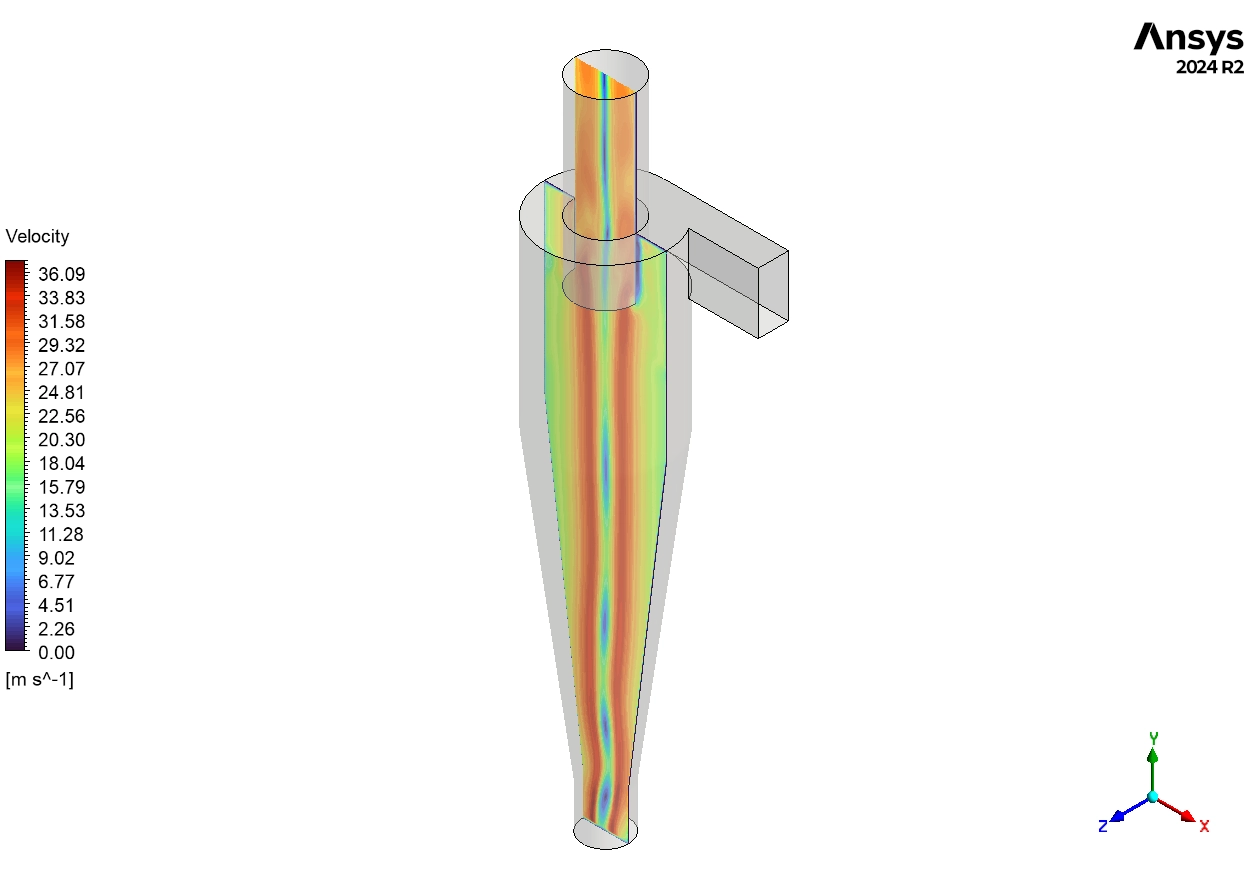

The velocity contour in Figure 5 shows us the engine of the separation process. The red and orange colors near the cyclone wall show that the air is spinning extremely fast, reaching a maximum speed of 36.09 m/s. This high-speed rotation creates a strong centrifugal force—the same force you feel on a merry-go-round—that throws the heavier dust particles out against the wall. The downward-spiraling outer vortex then carries these collected particles to the bottom of the cyclone to be removed. The clean gas, which is much lighter, stays in the middle and is pulled up the inner vortex and out of the cyclone. The simulation also calculated the pressure drop to be 1073.7186 Pa. This number is the energy “cost” needed to push the gas through the cyclone and is very important for choosing the right fan for the system.

Figure 4: Velocity streamlines from the Fluent simulation, showing the classic cyclone flow pattern with an outer downward vortex and an inner upward vortex.

Figure 5: The velocity magnitude contour on a cross-section of the cyclone, showing the high-speed spinning flow near the walls that is responsible for particle separation.

This Cyclone Separator CFD Validation is extremely valuable for the people who design and build these machines:

- It Creates a Trusted Digital Tool: By successfully matching the experimental data, we have turned a CFD simulation into a trusted digital prototype. Engineers no longer have to rely on old equations or guesses.

- It Allows for Rapid and Cheap Optimization: A company can now use this validated model to test new ideas on a computer. They can ask, “What happens if we make the inlet bigger?” or “What if we make the cyclone taller?” and get an accurate answer in a few hours. This is thousands of times faster and cheaper than building and testing many real cyclones.

- It Leads to Better Products: The final goal is always to design a cyclone that has the highest possible particle collection efficiency with the lowest possible pressure drop (energy cost). This validated simulation is the perfect tool to find that perfect balance, helping companies to create better, more efficient, and more competitive products for the market.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€175 Original price was: €175.€160Current price is: €160.

€170 Original price was: €170.€155Current price is: €155.

€220 Original price was: €220.€155Current price is: €155.

€265 Original price was: €265.€155Current price is: €155.

€120 Original price was: €120.€75Current price is: €75.

€320 Original price was: €320.€175Current price is: €175.

1 review for Cyclone Separator CFD Validation Study Using ANSYS Fluent

M.Naveed Baloch –

Perfect