Nuclear Power Reactor CFD Simulation of a Hot Fuel Rod Using a UDF

Nuclear Power Reactor CFD Simulation of a Hot Fuel Rod Using a UDF

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€150 Original price was: €150.€140Current price is: €140.

A nuclear power reactor CFD simulation is one of the most important safety studies in the energy industry. Inside a reactor, a fuel rod of the nuclear power reactor becomes extremely hot as it generates energy. This intense heat must be removed constantly and safely. If the cooling is not perfect, the fuel rod can overheat, which can lead to a very dangerous accident. A nuclear power reactor Fluent analysis is the only way for engineers to look inside the reactor core and see exactly how this critical cooling process is working.

This report shows an advanced fuel rod of the nuclear power reactor CFD simulation that uses a very special tool called a User-Defined Function (UDF). In a real reactor, the heat is not the same all the way along the fuel rod; it is hottest in the middle and cooler at the ends, following a special cosine-shaped pattern. A normal simulation cannot do this. The UDF is a piece of custom computer code that allows engineers to program this real-world physics directly into ANSYS Fluent. This makes the simulation incredibly accurate. This study is essential for making sure the reactor design is safe, for finding the best way to cool the fuel rods, and for keeping the entire nuclear power plant operating safely and efficiently.

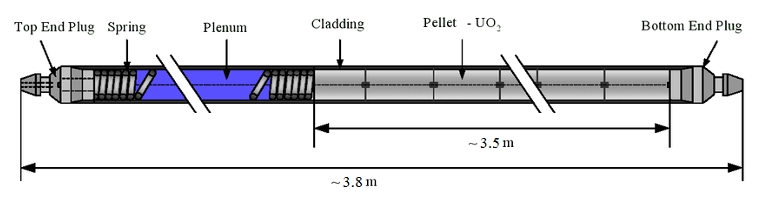

Figure 1: A schematic showing the different parts of the nuclear fuel rod assembly used in the model.

Simulation process: Modeling the Nuclear Heat Source

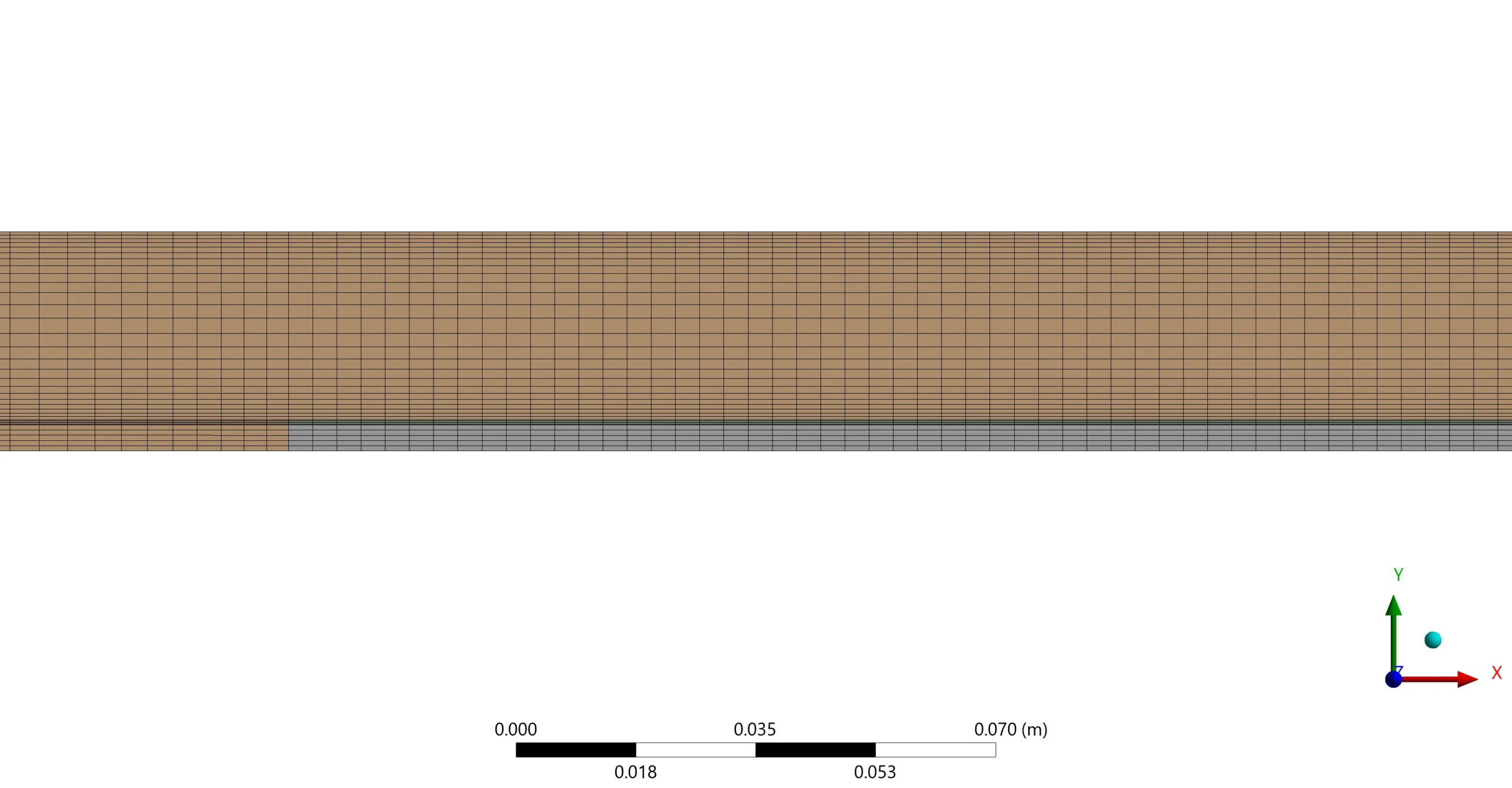

The simulation process for this nuclear power reactor CFD study began with creating a 2D axisymmetric computer model. An axisymmetric model is a very smart and efficient choice for this problem because the fuel rod is perfectly round, which means we can get a full 3D result by simulating just one 2D slice. The entire model was then filled with a high-quality, structured grid made of 55,870 quad cells. A structured grid, with its organized, rectangular cells, is the best choice for this kind of heat transfer problem because it gives the most accurate results for temperature calculations, especially near the walls of the fuel rod where the biggest changes happen.

Inside ANSYS Fluent, the complex physics of the nuclear reactor was carefully defined. The most important part of this simulation was the use of a User-Defined Function (UDF) to model the heat source. The heat generated by the fuel rod is not constant; it follows a cosine distribution along its length, which is described by the formula:

q”(z) = q_max × Cos(π/H × z)

This formula was programmed into a UDF and applied to the fuel region. This is a critical step because it makes the simulation behave exactly like a real nuclear reactor. The model included all the different materials: the uranium fuel, the helium gas gap, the solid control rod, and the flowing water coolant, each with its own properties, to create a complete and realistic virtual model of the reactor core.

Figure 2: A zoomed-in view of the high-quality, structured grid with 55,870 quad cells used for the axisymmetric CFD simulation.

Post-processing: A CFD Engineering Performance of Nuclear Power Reactor

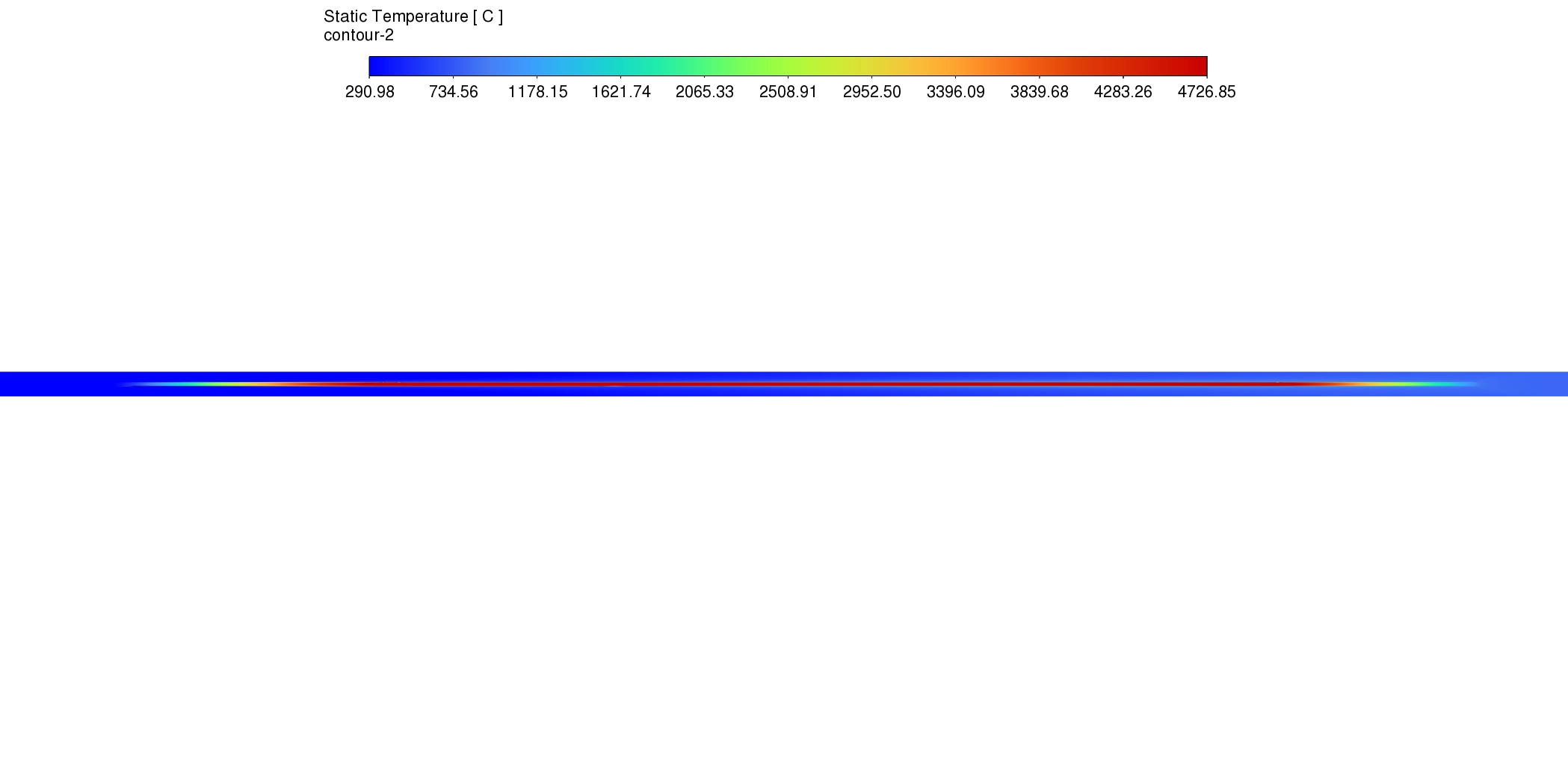

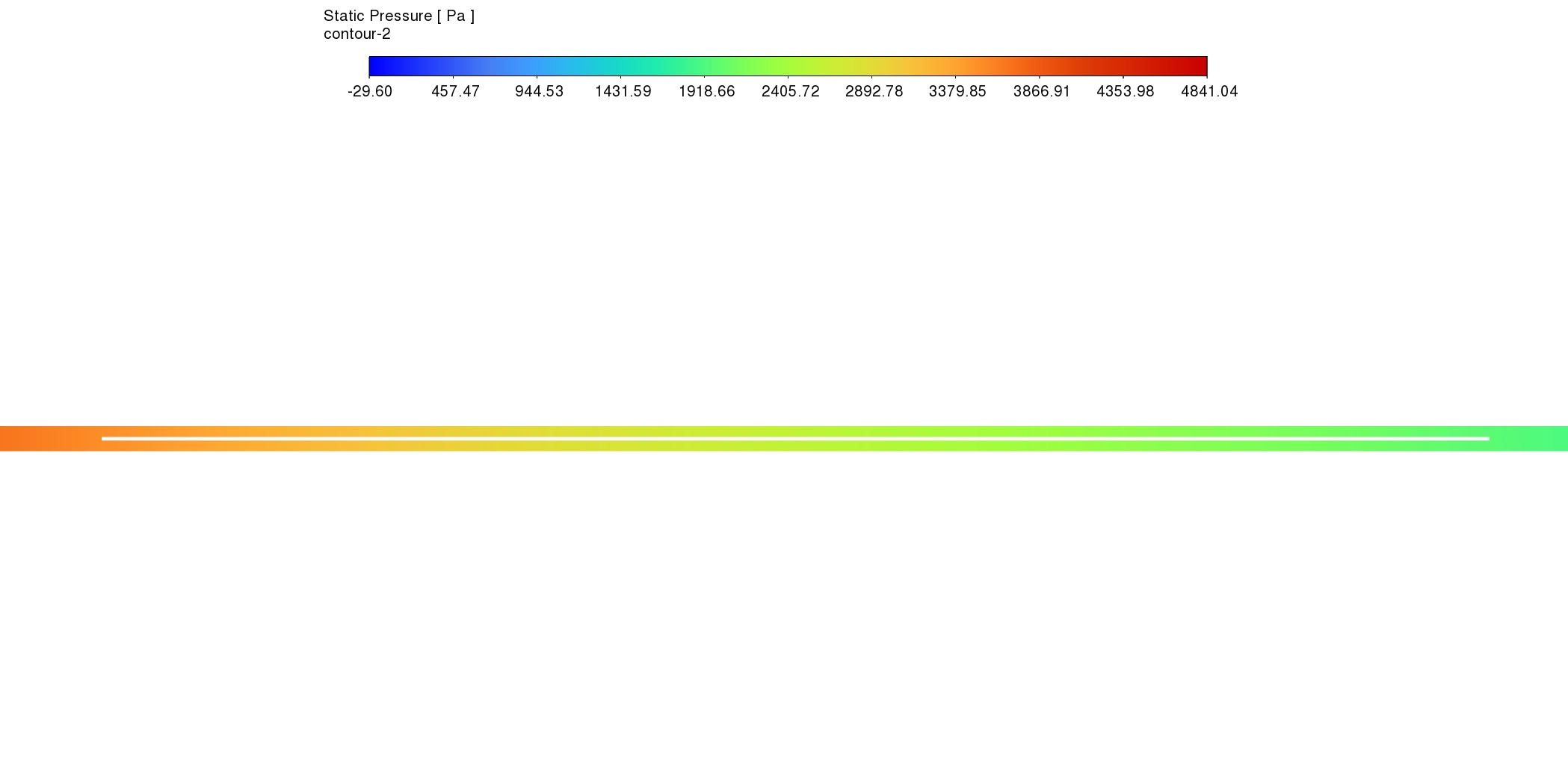

The simulation results give us a complete picture of the conditions inside the reactor core. We will now conduct a two-stage audit to confirm that the reactor is operating safely and performing well. First, we must confirm that the extreme heat generated by the fuel rod is being managed safely. The temperature contour in Figure 4 gives us the big picture. We can see an enormous temperature range, from the blue water at 290.98°C to the bright red center of the fuel at 4726.85°C.

The data table gives us the precise numbers for our audit. The average temperature of the fuel is 4091.19°C, while the average temperature of the water is only 660.13°C. This shows a massive temperature difference of over 3400°C between the heat source (the fuel) and the cooling system (the water). This is the most important result of the entire simulation. It is clear, direct proof that the cooling system is working extremely well. It is successfully pulling the dangerous heat out of the fuel and moving it into the water. The final piece of evidence is the average outlet water temperature of 847.90°C. The water enters cool and leaves hot, which proves it has successfully absorbed and carried away the nuclear heat.

| Component | Volume-Average Temperature [°C] |

| Water | 660.13 |

| Rod | 3970.05 |

| Helium | 4024.69 |

| Fuel | 4091.19 |

| Outlet | 847.90 |

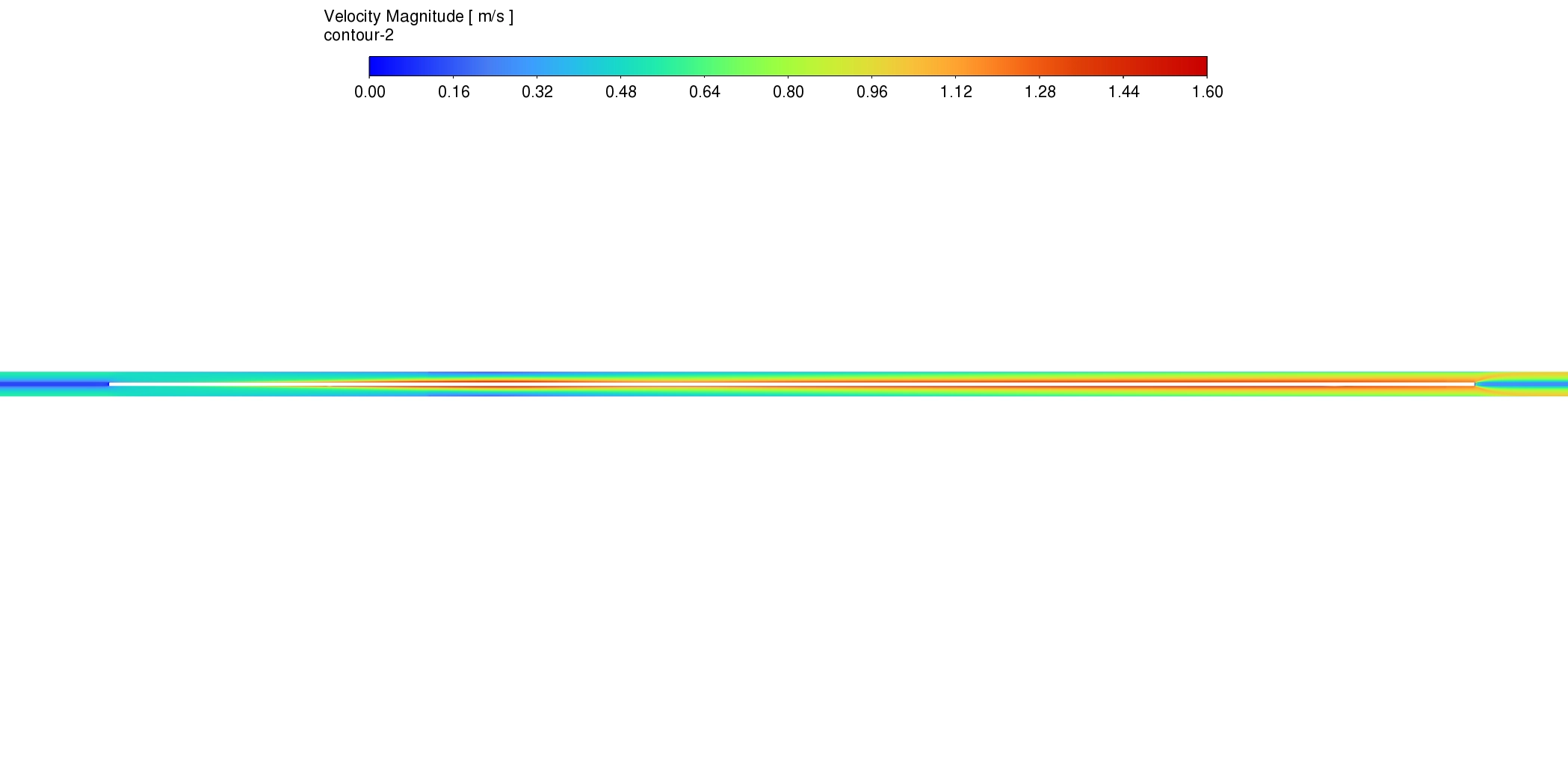

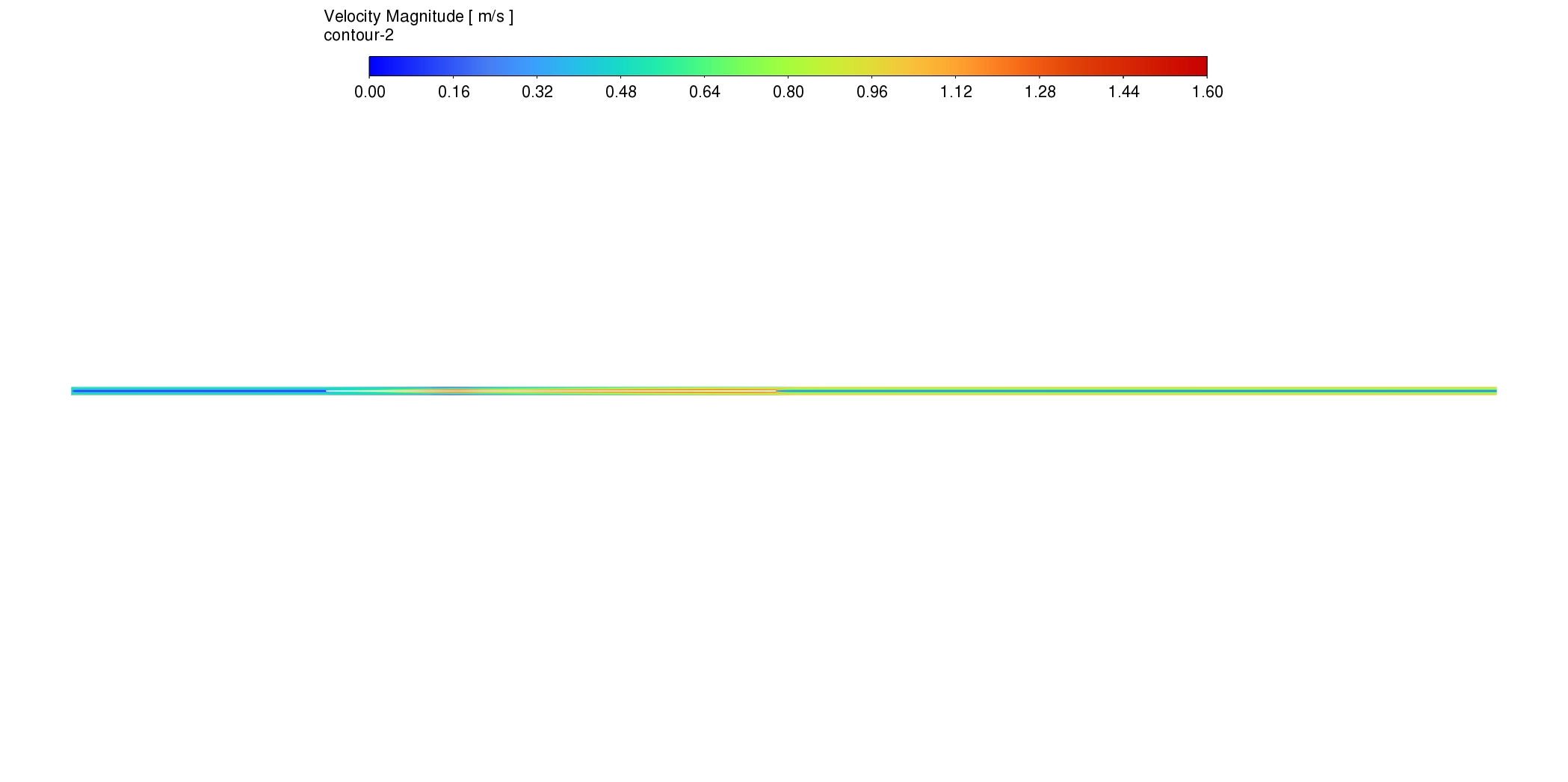

Now that we have confirmed that the heat is being removed, we will inspect the cooling system to see how it works so well. The velocity contour in Figure 3 shows us the cooling system in action. The water flows through the channels between the hot fuel rods. As it flows, it speeds up in the narrow gaps, reaching a top speed of 1.60 m/s.

This contour explains the secret to the successful cooling we saw in Stage 1. The design of the reactor core forces the water to flow fastest right next to the hottest surfaces. This high-velocity flow acts like a very effective scrubber, constantly washing the intense heat off the surface of the fuel rods. The simulation proves that the coolant is being sent exactly where it is needed most. This direct connection between the high-speed flow and the high-heat areas is the key to the safe thermal management of the entire reactor.

Figure 3: The velocity magnitude contour from the Fluent simulation. It shows the speed of the cooling water as it flows through the channels between the fuel rods, from 0.00 m/s to 1.60 m/s.

Figure 4: The static temperature contour from the CFD simulation. This shows the extreme temperature difference, from the hot fuel centerline (4726.85°C) to the much cooler water (290.98°C).

This nuclear power reactor CFD simulation is more than just a set of results; it is a critical safety and design tool for engineers:

- It is a Virtual Safety Check: The most important job of a nuclear engineer is to ensure safety. This simulation allows them to check the maximum fuel temperature under different power conditions. They can prove that the temperature will always stay below the material’s melting point, which is the number one rule of nuclear safety.

- It Allows for Design Optimization: This simulation is a perfect virtual test bench. Engineers can test different designs on the computer. For example, they could change the spacing between the fuel rods or change the speed of the water pumps. The simulation will tell them which design gives the best cooling performance for the lowest amount of pumping energy.

- The UDF Provides Ultimate Realism: Because the heat source is controlled by a UDF, engineers can easily test any power scenario. They can see what happens if the power is increased, or if the heat is distributed differently. This makes the simulation an extremely powerful and realistic tool for verifying the safety and performance of the reactor design before it is ever built.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€210 Original price was: €210.€185Current price is: €185.

€160 Original price was: €160.€135Current price is: €135.

€325 Original price was: €325.€195Current price is: €195.

€165 Original price was: €165.€125Current price is: €125.

€120 Original price was: €120.€65Current price is: €65.

€245 Original price was: €245.€185Current price is: €185.

Reviews

There are no reviews yet.