Sand Battery Simulation Tutorial: A CFD Analysis of Thermal Charging in ANSYS Fluent

Sand Battery Simulation Tutorial: A CFD Analysis of Thermal Charging in ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€155 Original price was: €155.€140Current price is: €140.

A Sand Battery is a new and simple way to store green energy. When solar panels or wind turbines make extra electricity, we can use it to heat a large, insulated tank full of sand. Sand is very cheap and can stay hot at very high temperatures (over 500°C) for a long time. This stored heat can later be used to warm homes in the winter. To design these systems, engineers use a CFD Analysis of Sand Battery. We cannot see how heat moves inside a giant tank of hot sand, so we use ANSYS Fluent to simulate it.

This simulation calculates three types of heat transfer. First is conduction, where heat moves through the solid sand grains. Second is convection, where heat moves through the small air gaps. Third is radiation, where heat travels as invisible rays between the hot grains. This Sand Battery Fluent simulation helps us find the best pipe size and sand type. It makes sure the system is efficient and does not waste energy. For more examples of thermal simulations, please explore our Heat Transfer tutorials.

Figure 1: Sand Trapping, showing the concept of using sand as a thermal storage medium.

Simulation Process: Setting Up the Sand Battery CFD Simulation in ANSYS Fluent

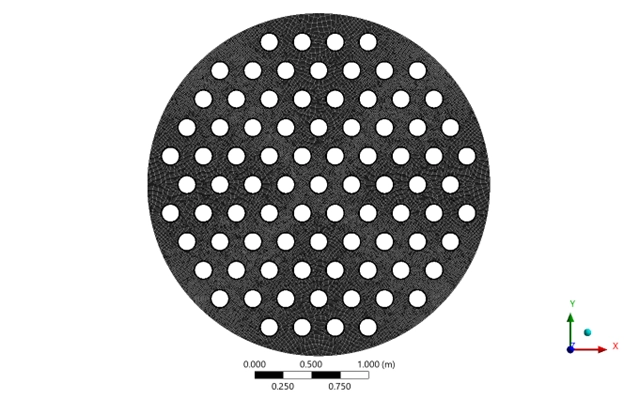

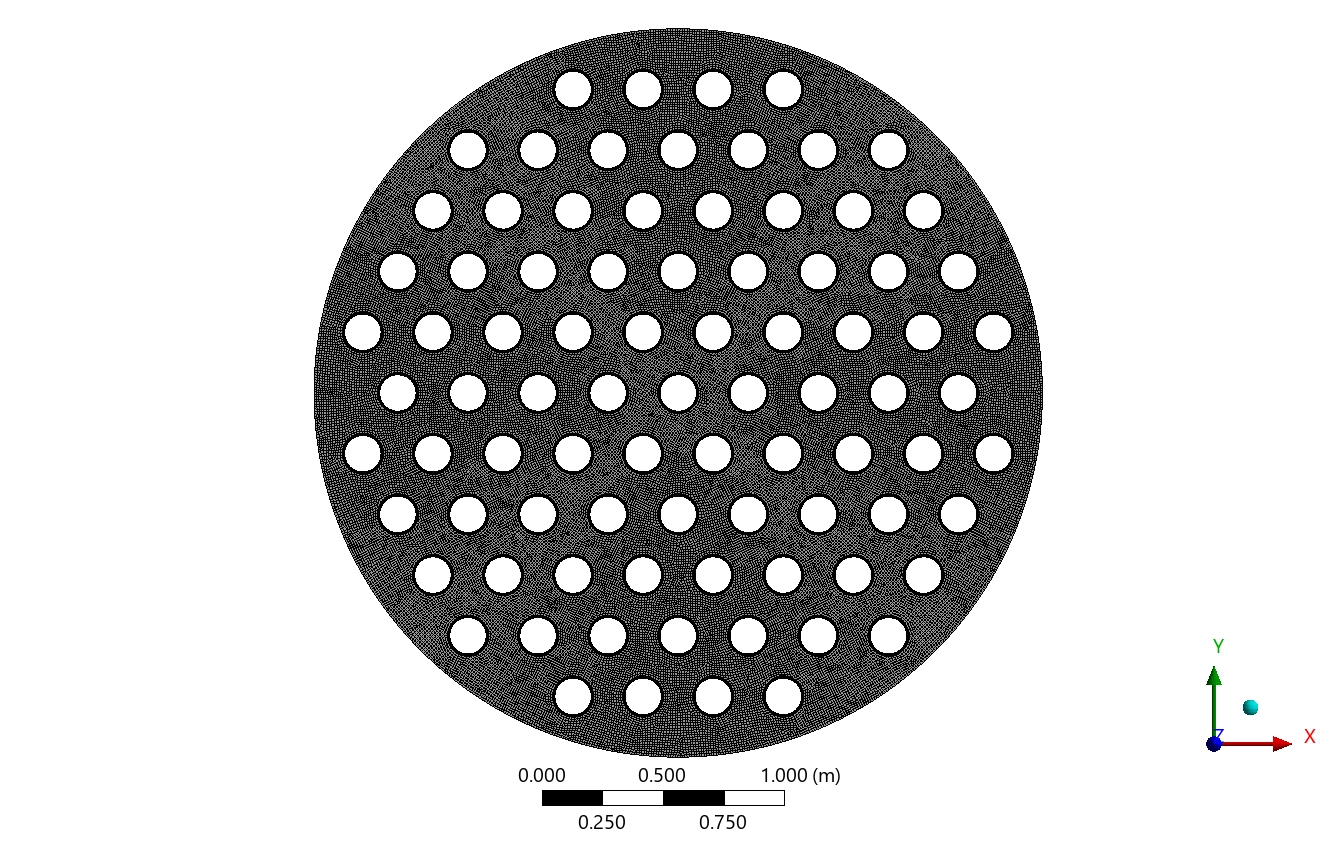

For this project, we modeled a vertical slice of the round tank. This is a 2D model, which is a smart shortcut. It gives us the same accurate results as a full 3D model but runs much faster. We created a mesh with 72,175 cells. Look at Figure 2. You can see we made the cells much smaller right next to the circular pipes. We do this because the temperature changes very fast in these locations. Small cells capture these rapid changes accurately, while larger cells away from the pipes save computer power.

The most important part of the setup is defining the physics. We turned on the S2S Radiation Model (Surface-to-Surface). This is not optional. At the very high temperatures inside a sand battery (over 500°C), everything glows with thermal radiation. This model calculates how heat radiates from one sand grain to another. We set the hot air inside the pipes to a constant 650°C. We then ran a transient simulation. This means we solved the problem over a period of 16,000 seconds (about 4.4 hours) to watch the heat slowly spread from the pipes into the sand.

Figure 2: Unstructured Grid generation in ANSYS Fluent with 72,175 cells, showing the 2D axisymmetric domain and mesh refinement near the circular pipes.

Post-processing: A Deep Sand Battery CFD Analysis of Heat Transfer

In this section, we will act as engineers and judge if this design is good or bad. We will analyze the data to give clear recommendations to a manufacturer.

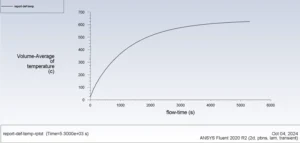

First, let’s analyze the Heating Rate Graph in Figure 4. This graph shows the average temperature of the sand over time. For the first 2,000 seconds (about 30 minutes), the line on the graph is extremely steep. The temperature shoots up from 25°C to almost 500°C. This is the Fast Charging Phase. The reason is simple physics: the pipes are very hot (650°C) and the sand is very cold (25°C). This huge temperature difference acts like a strong pressure, forcing heat into the sand very quickly. However, after this point, the line becomes almost flat. This is the Slow Charging Phase. The sand is now almost as hot as the pipes, so the temperature difference is small. This means the “pressure” pushing the heat is very weak. The graph proves that charging this battery for more than two hours is a waste of electricity. The most efficient charging happens at the beginning. A manufacturer should program the system to stop charging after about two hours to maximize efficiency and save operational costs.

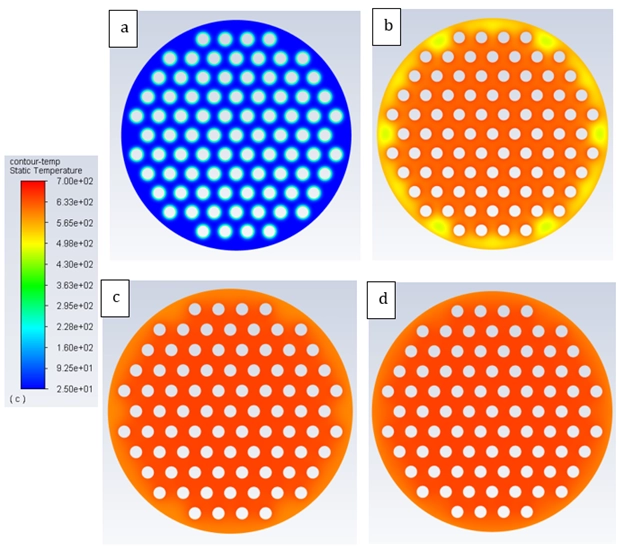

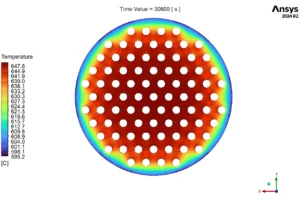

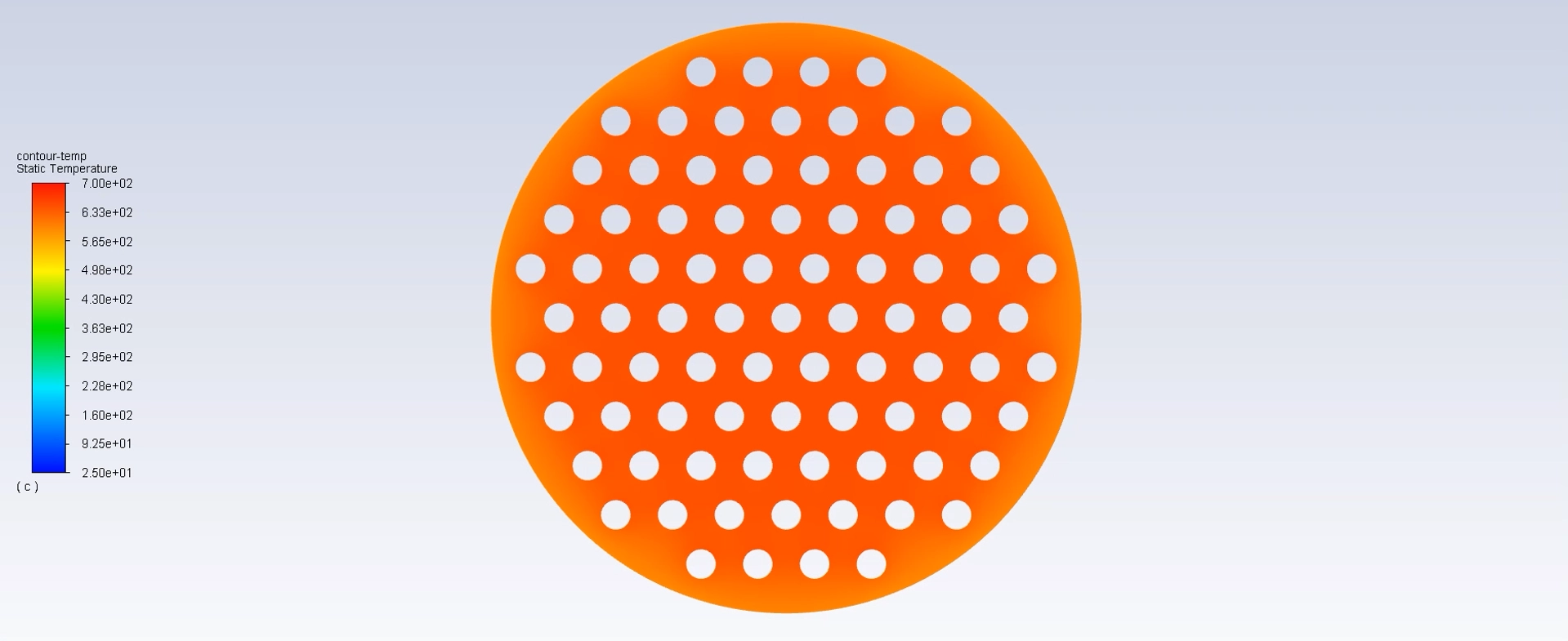

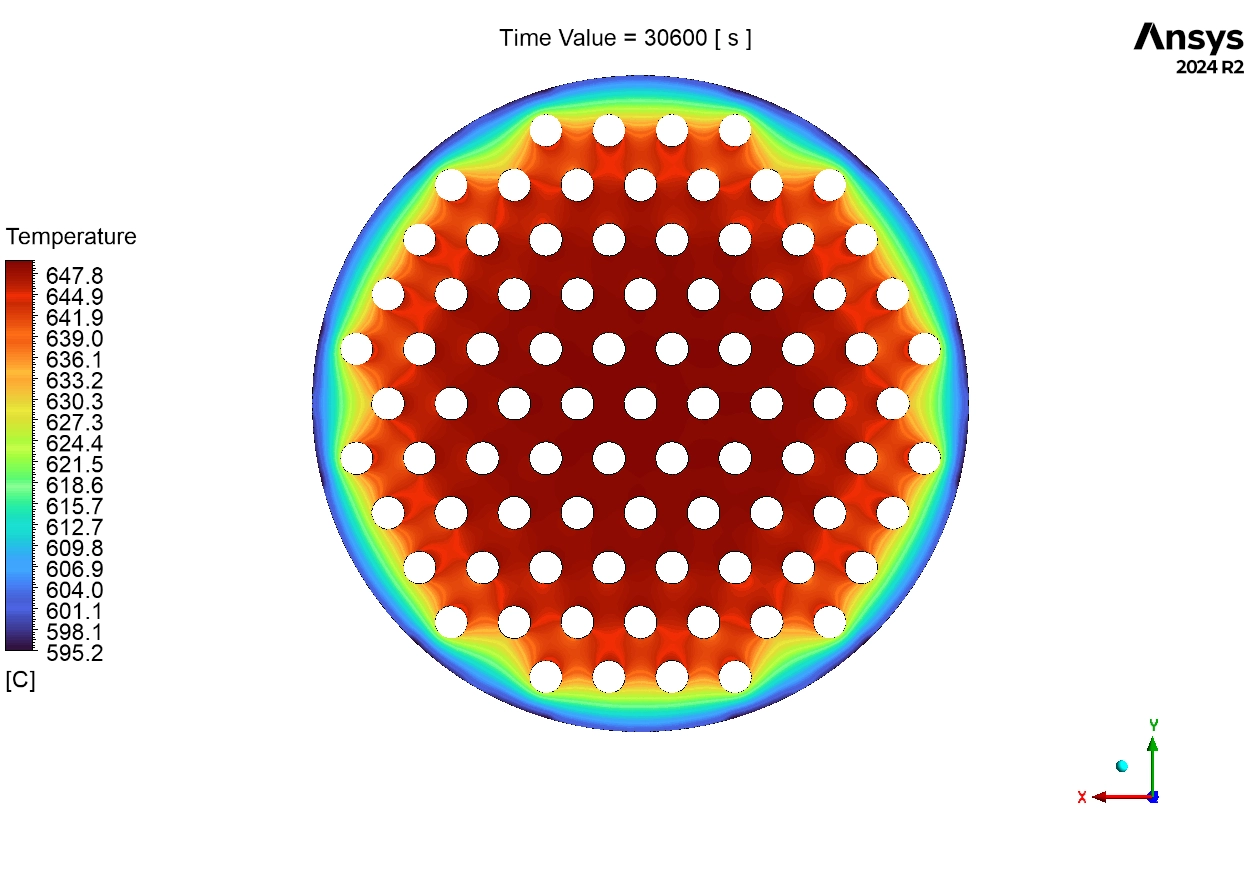

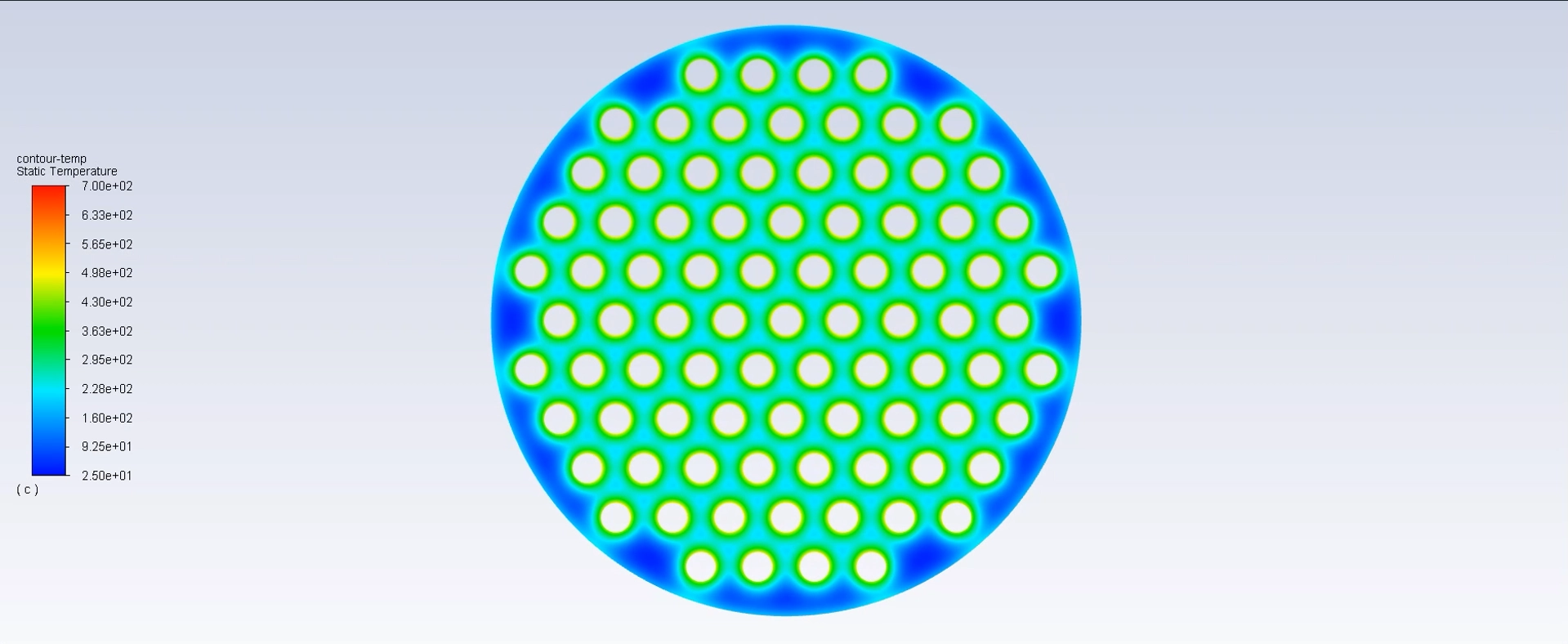

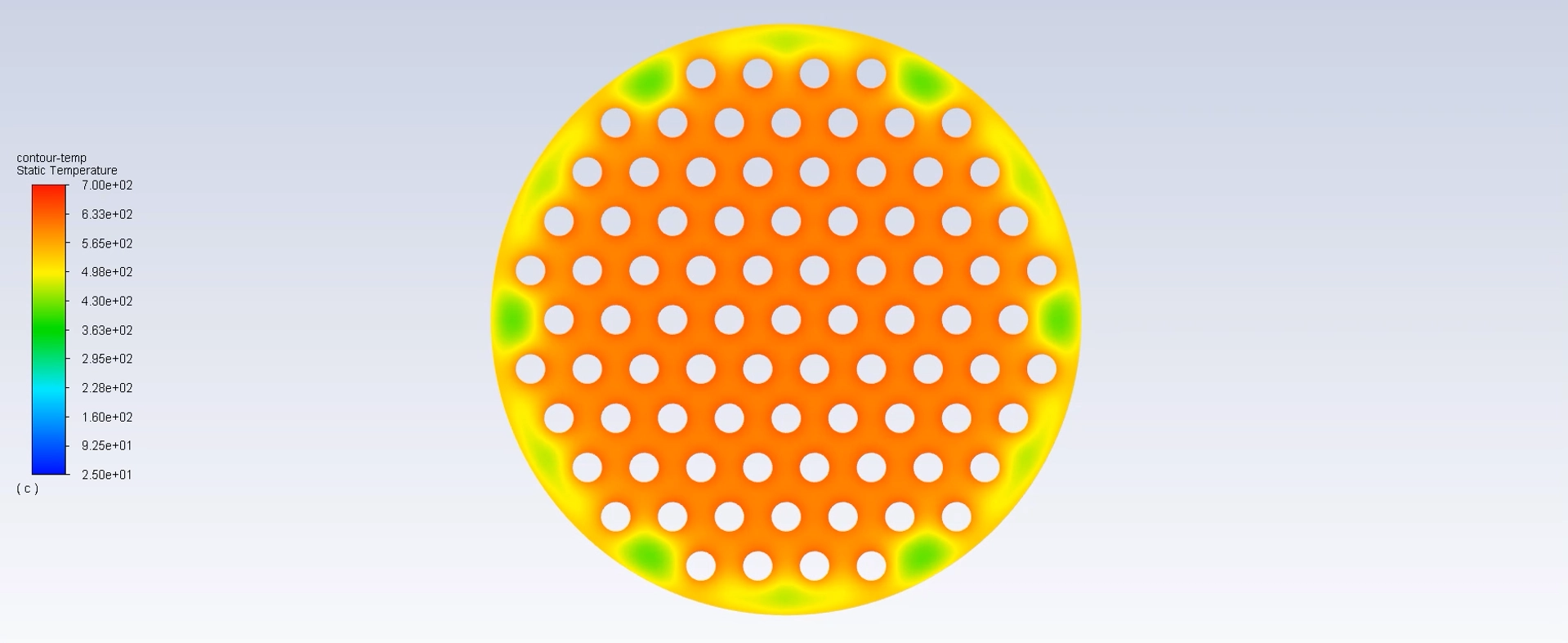

Next, we will examine the Temperature Contours in Figure 3. These images are like thermal photographs. At 2 minutes, the image is mostly dark blue (cold). This tells us that sand is a poor conductor of heat. Heat moves through it very slowly, which is actually good for storage. Now look at the image for 1 hour. The inside of the tank is a uniform orange color. This is a Good Design Feature. It means the pipes are spaced correctly. The heat from each pipe has spread out and joined with the heat from its neighbors, leaving no cold spots in between. The entire core of the battery is being heated evenly.

However, these images also reveal a Critical Design Flaw. Look closely at the final image (t=4 hours). While the center is hot and stable, there is a thin blue ring around the outer edge. This blue ring represents heat that is escaping the tank. A battery’s job is to store energy, not lose it. This heat loss means the battery will cool down over a few weeks or months, which defeats its purpose. This is a Poor Design for long-term storage. Final Recommendation: The Sand Battery CFD Analysis shows that while the internal pipe layout is effective, the external insulation is not. The manufacturer must use a thicker layer or a better type of insulation material on the outside of the tank to trap the heat. Fixing this flaw will allow the battery to store energy efficiently for the entire winter season.

Figure 3: Temperature Contours at four different time steps (2 mins, 1 hr, 2 hrs, 4 hrs), visualizing the radial heat propagation from the pipes into the sand bed.

Figure 4: Volume-Average Temperature vs. Flow Time, plotting the rapid initial heating phase followed by the slow approach to thermal equilibrium.

Key Takeaways & FAQ

- Q: Why does the battery charge fast and then slow down?

A: At the start, the large temperature difference between the hot pipes and cold sand pushes heat in quickly. Later, when the sand is hot, this difference is small, so charging slows down.

- Q: Is sand a good conductor of heat?

A: No, it is a poor conductor. Heat moves through it slowly. This is bad for fast charging, but very good for long-term storage because it helps trap the heat inside.

- Q: What is the main problem with this Sand Battery design?

A: The main problem is poor insulation. The simulation shows a “blue ring” of heat loss on the outer edge, meaning it will not store energy for very long. The insulation must be improved.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€140 Original price was: €140.€130Current price is: €130.

€170 Original price was: €170.€125Current price is: €125.

€160 Original price was: €160.€85Current price is: €85.

€120 Original price was: €120.€75Current price is: €75.

€160 Original price was: €160.€80Current price is: €80.

€245 Original price was: €245.€185Current price is: €185.

Reviews

There are no reviews yet.