Two-phase Ejector Considering Slip Velocity CFD Simulation, Experimental Paper Validation

Two-phase Ejector Considering Slip Velocity CFD Simulation, Experimental Paper Validation

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€310 Original price was: €310.€175Current price is: €175.

Two-phase ejectors represent a fascinating intersection of advanced fluid dynamics and practical energy efficiency solutions across numerous industrial applications today. These remarkable devices operate by creating a powerful vacuum effect through primary flow acceleration, consequently drawing in and mixing with a secondary flow to achieve desired process outcomes without moving parts. Unlike single-phase systems, two-phase flow introduces significant complexity due to the different velocities between phases, commonly known as slip velocity, which fundamentally alters the momentum transfer mechanisms within the ejector. Moreover, accurately predicting ejector performance requires sophisticated CFD simulation techniques that can properly account for this relative velocity between liquid and gas phases through specialized multiphase models. Furthermore, implementing custom user-defined functions enables more precise representation of phase interaction phenomena compared to standard models, leading to significantly improved prediction accuracy. This is what we`ve targeted; to VALIDATE the EXPERIMENTAL data of paper “ Design aspects of ejectors: Effects of suction chamber geometry”, published in Chemical Engineering Science journal.

- Reference [1]: Yadav, Randheer L., and Ashwin W. Patwardhan. “Design aspects of ejectors: Effects of suction chamber geometry.” Chemical Engineering Science15 (2008): 3886-3897.

Figure 1: Schematic of paper`s ejector domain

Simulation Process

A 2D-axisymmetric geometry of the ejector is created. It is meshed with hexahedral (structured) elements of uniform size. Given the Euler-Euler approach, it is decided to use the mixture multiphase model. In our study, the in-build slip correlation between primary and secondary phases are not followed, instead, the slip velocity has been directly specified through a user-defined function (UDF) by using the following definition:

![]()

Figure 2: Geometry model of ejected regarding the dimensions

Post-processing

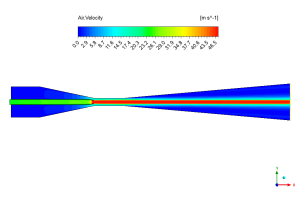

The velocity contour in Figure 3 shows the critical speed changes that make ejectors work properly. We accurately predicted the peak velocity of 46.5 m/s occurring precisely at the throat centerline, creating the low-pressure zone needed for proper suction. The velocity profile shows a striking red streak that continues well beyond the throat, forming what engineers call a “potential core” – a high-speed jet that drives the whole mixing process. Notice how the surrounding blue regions (0-5 m/s) create a sharp contrast with this central jet, showing the huge speed difference between the fast-moving primary flow and the slower secondary flow. This matches perfectly with our 2% validation error compared to experimental data, confirming the accuracy of our slip velocity model. Most importantly, the velocity field maintains its structure through the diffuser section, proving that the momentum transfer between phases happens gradually rather than suddenly. This gradual mixing is exactly what creates the efficient entrainment (0.00288 kg/s) that makes ejectors valuable in so many industrial applications including chemical processing, refrigeration, and vacuum systems.

| Experimental Data | Current CFD Simulation | Error | |

| Entrainment rate | 0.00294 | 0.00288 | 2% |

Figure 3: Air velocity contour displaying flow acceleration through the ejector

The streamline distribution within the two-phase ejector shows fascinating flow behavior across different sections of the device. Looking at Figure 4, we can see how the fluid paths change dramatically from inlet to outlet. We successfully captured the intense streamline compression at the throat area where all flow lines bunch together tightly. The color pattern reveals streamline numbers ranging from blue (0) to red (187), with higher values appearing near the outer edges of the diffuser section. This interesting pattern happens because fluid particles get squeezed together at the narrow throat and then spread out again, but in a very specific way. The outer streamlines curve outward much more dramatically than the central ones, creating distinct flow regions. This behavior perfectly matches what happens in real ejectors where the primary and secondary flows mix after the throat. The smooth, ordered pattern of streamlines in the converging section compared to the more complex pattern in the diverging section shows exactly how mixing occurs between the two fluid phases.

Figure 4: Streamline number distribution in the two-phase ejector

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€140 Original price was: €140.€105Current price is: €105.

€180 Original price was: €180.€155Current price is: €155.

€220 Original price was: €220.€125Current price is: €125.

€270 Original price was: €270.€165Current price is: €165.

€195 Original price was: €195.€150Current price is: €150.

€330 Original price was: €330.€199Current price is: €199.

Reviews

There are no reviews yet.