Archimedes Screw Turbine CFD Simulation Using 6DOF Dynamic Mesh in Fluent

Archimedes Screw Turbine CFD Simulation Using 6DOF Dynamic Mesh in Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€170 Original price was: €170.€150Current price is: €150.

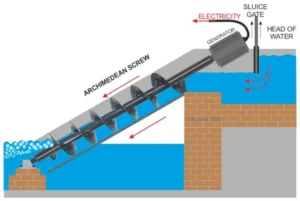

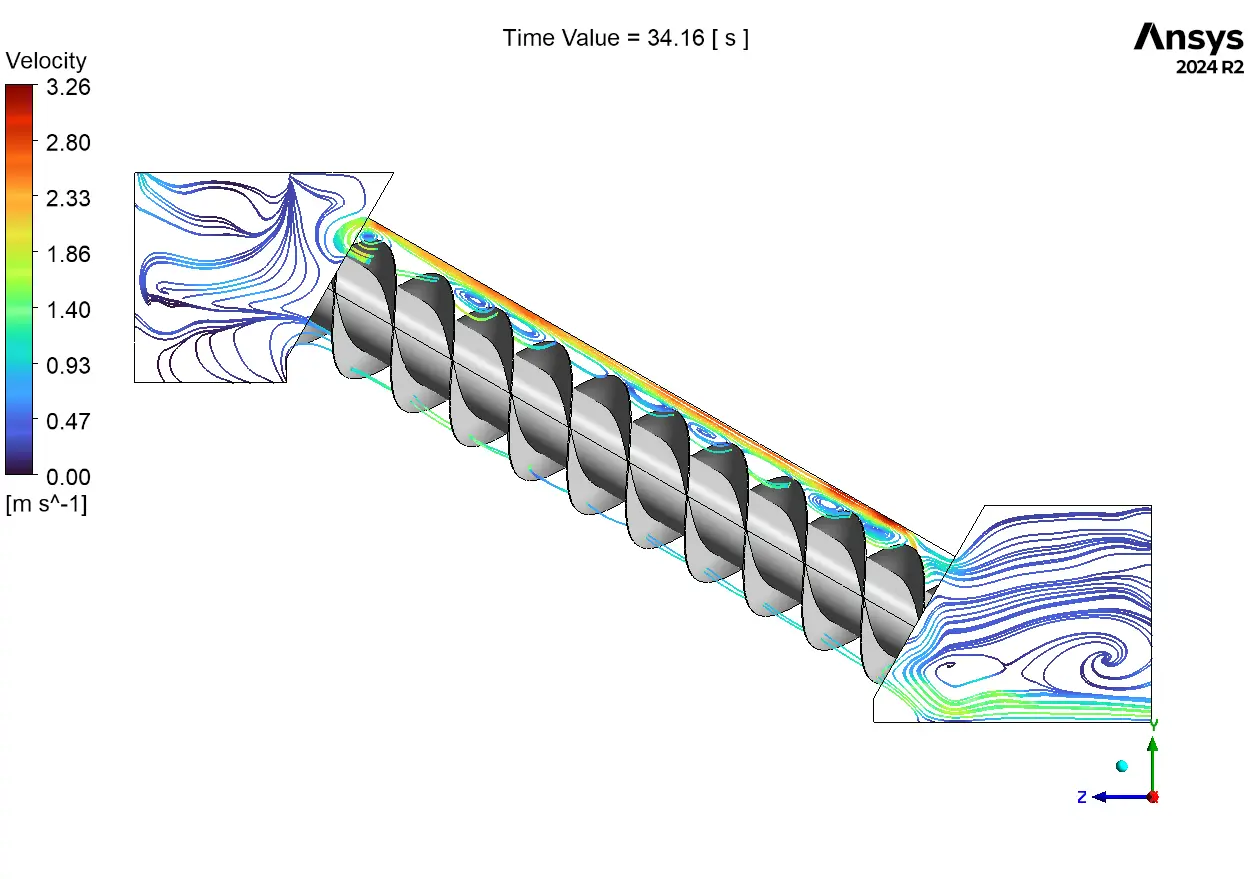

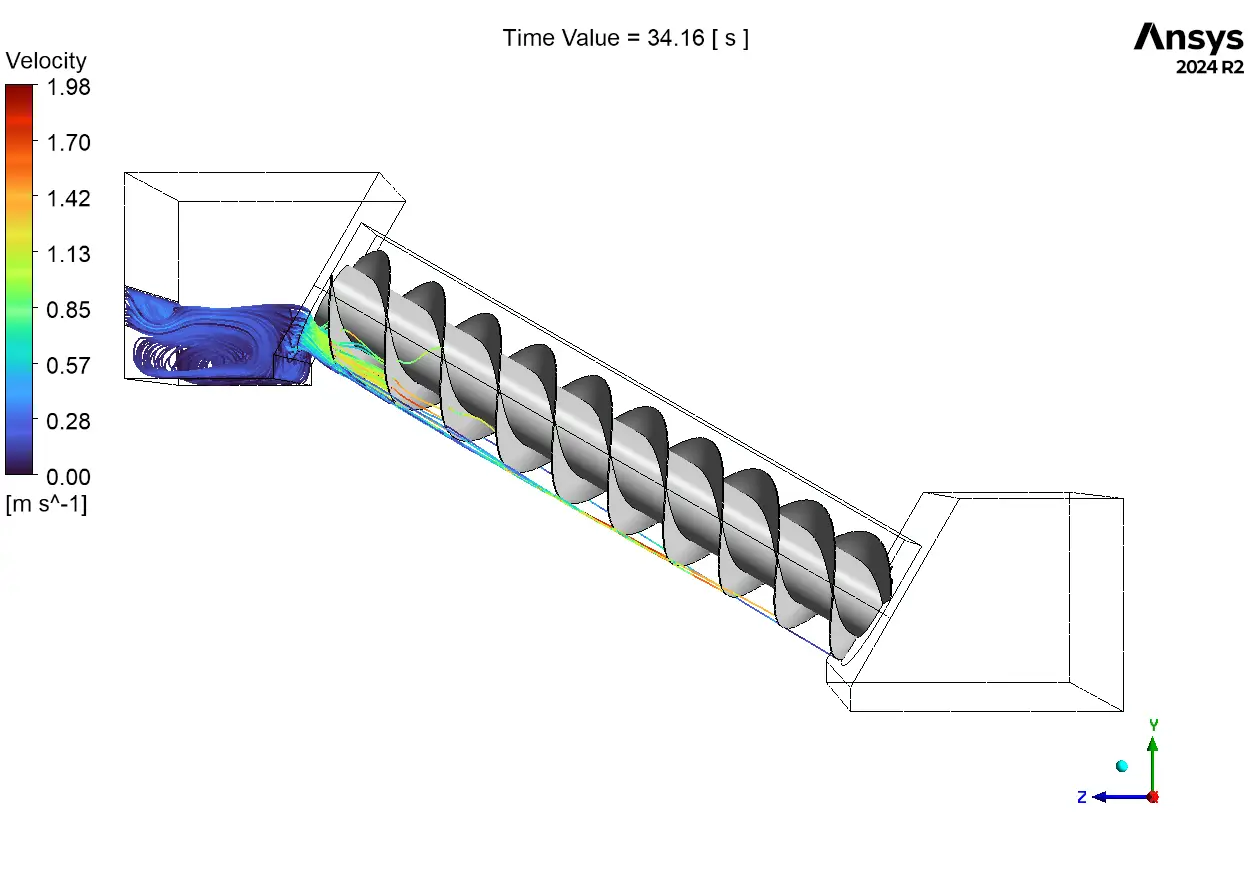

An Archimedes Screw Turbine CFD simulation is the key to designing efficient green energy systems for rivers and canals. Unlike high-speed turbines, the Archimedes screw works slowly and gently. It uses the weight of the water to push the blades and turn the shaft. An Archimedes Screw Turbine Fluent analysis allows engineers to see exactly how water flows through the screw buckets. This is difficult because the screw is always moving.

This report details a complex Screw Turbine CFD study. To make the simulation realistic, we use the 6DOF fluent simulation method (Six Degrees of Freedom). This means the computer does not force the screw to spin at a set speed. Instead, the water pushes the blades, and the software calculates how fast the screw should spin based on that force. This is the most accurate way to model reality. We also use Dynamic mesh fluent technology, which changes the shape of the computational grid as the screw rotates. This Screw Turbine ANSYS Fluent study provides the critical torque and power data needed to build better, more efficient hydropower plants. For those interested in mastering moving part simulations, our comprehensive dynamic mesh tutorials are available at https://cfdland.com/product-category/module/dynamic-mesh-cfd-simulation/

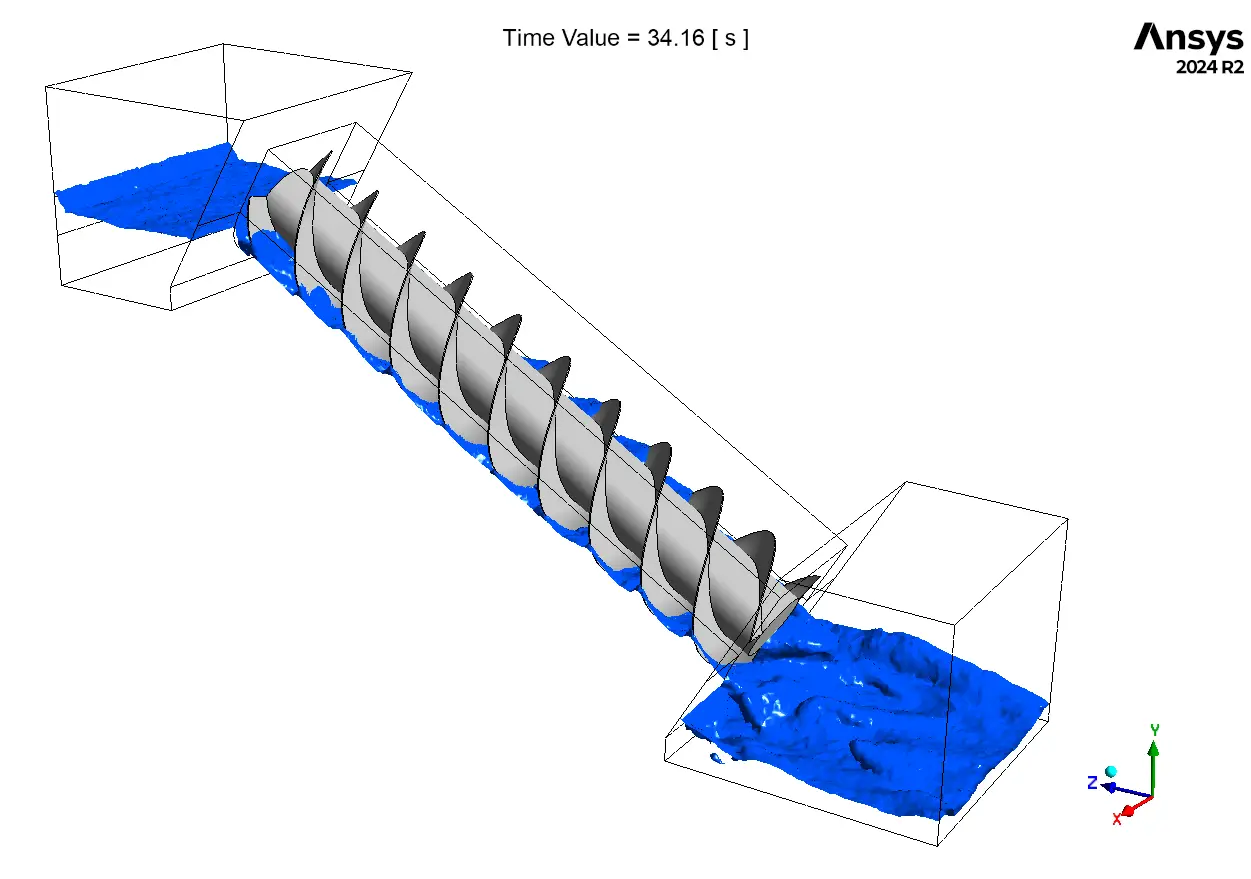

Figure 1: A schematic diagram of the Archimedes Screw Turbine showing the helical blades and the upstream and downstream water levels.

Simulation process: Fluent 6DOF & Dynamic Mesh Setup for Turbine Rotation

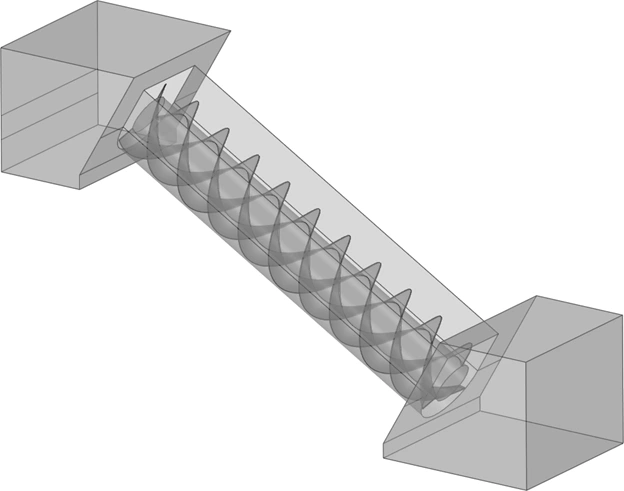

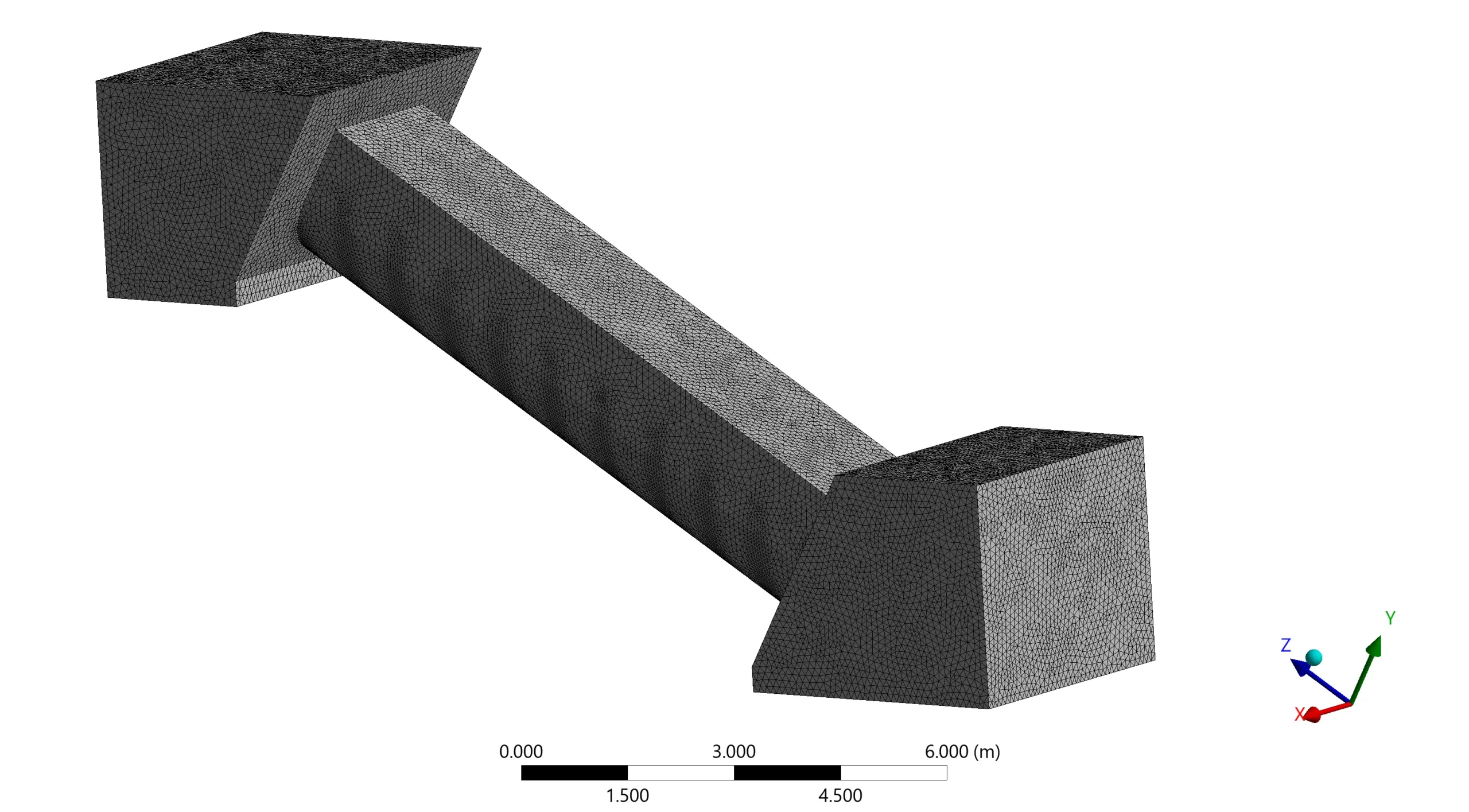

The simulation process for this Archimedes Screw Turbine CFD study began with a complete 3D model. The geometry included the screw with its helical blades, a reservoir at the top (inlet), and a pool at the bottom (outlet). The engineers generated a detailed mesh with 1,356,712 cells. A high number of cells is necessary to capture the thin layer of water leaking between the blade and the trough, which affects efficiency.

Inside ANSYS Fluent, the physics were set up to handle the complex motion. The VOF (Volume of Fluid) model was used to track the water and air. This is essential because the screw is an “open channel” device where the water level changes constantly. The most critical part was the 6DOF solver. The engineer told Fluent the weight and inertia of the screw, and the software calculated the rotation based on the water pressure. To handle this rotation, Dynamic Mesh was activated with smoothing and remeshing methods. This ensures that as the screw turns, the mesh cells stretch and rebuild themselves to stay high quality. The simulation was transient, meaning it calculated the flow step-by-step over time to show the startup and steady operation of the turbine.

Figure 2: The 3D geometry model used for the Archimedes Screw Turbine CFD simulation, including the upstream inlet, the rotating screw domain, and the downstream outlet.

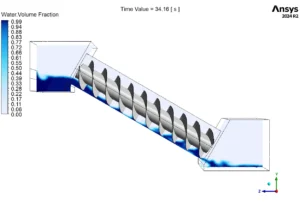

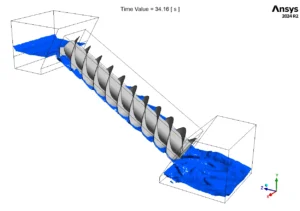

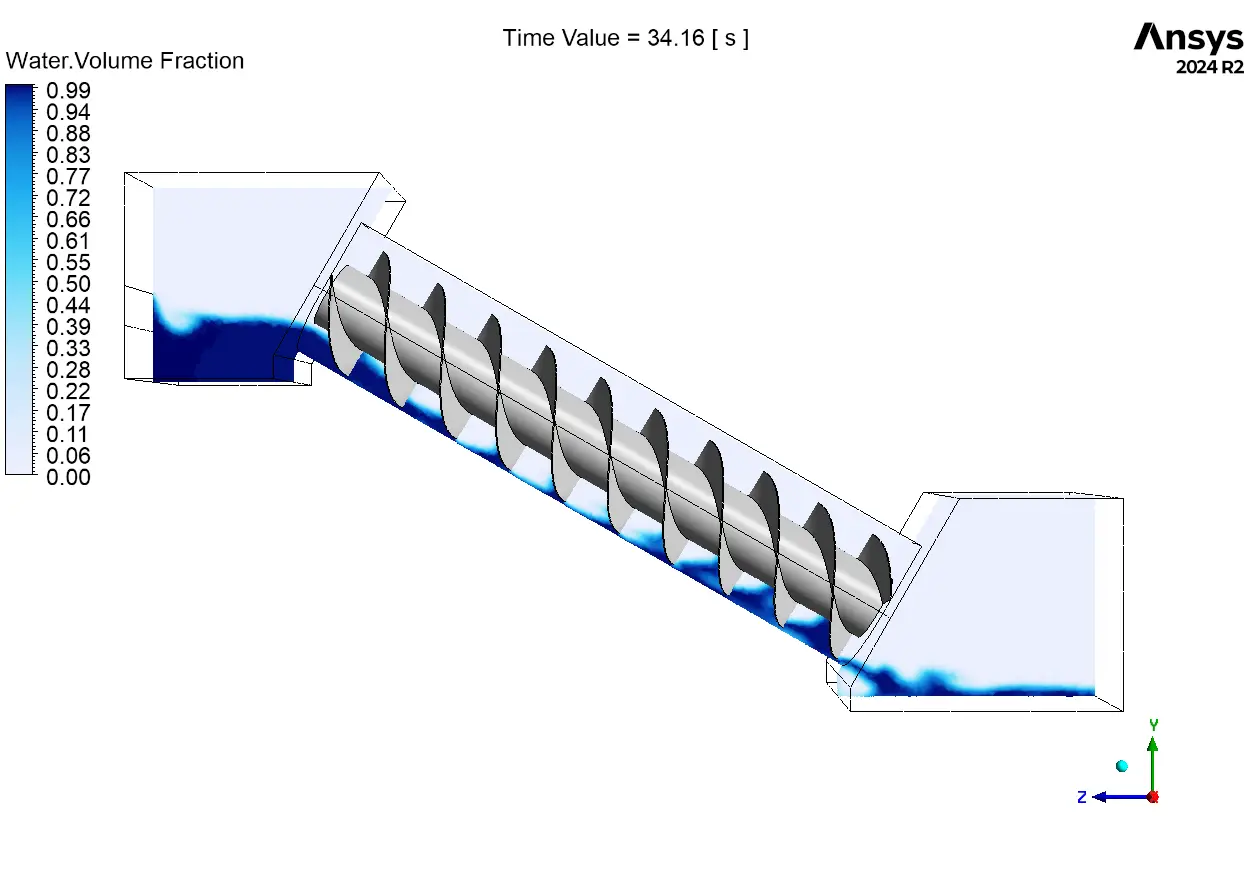

Post-processing: Hydraulic Performance of Screw Turbine

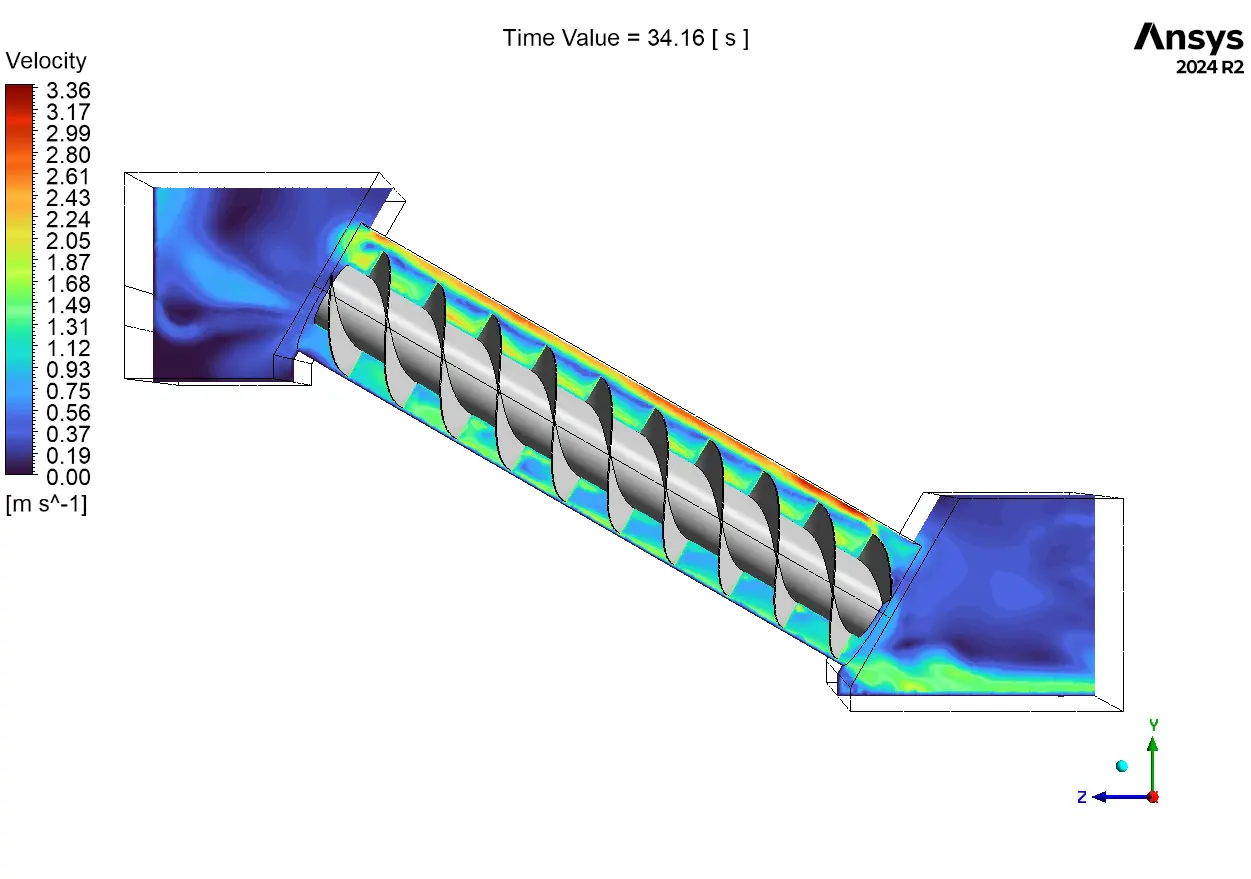

The simulation results provide a comprehensive engineering assessment of how effectively the turbine converts hydraulic potential energy into mechanical work. By analyzing the flow distribution and the resulting forces, we can evaluate the efficiency of the design. The water volume fraction contours in Figure 3 allow us to visually inspect the hydraulic behavior inside the machine at the simulation time of 34.16 seconds. The contours reveal that water enters from the upstream domain and flows down into the helical chambers. As the water pushes against the inclined blades, gravity forces the fluid to the bottom of each bucket, creating a stable “partial filling” condition. The contours confirm that the buckets are not completely full while the upper section of each chamber remains filled with air. This is a critical engineering insight because it proves the turbine is sized correctly for this flow rate; if the buckets were 100% full, water would spill over the central shaft, leading to significant energy loss and reduced efficiency. The VOF model successfully captures the smooth interface between the water and air, confirming that the dynamic mesh is handling the rotation without causing artificial diffusion or numerical errors in the fluid tracking.

Figure 3: Water volume fraction contours from ANSYS Fluent VOF model showing multiphase flow distribution in the Archimedes Screw Turbine with 6DOF dynamic mesh at time = 34.16 seconds.

The most valuable data for the manufacturer comes from the force calculations provided by the 6DOF solver. At the stable operating point of 34.16 seconds, the water pressure acting on the blade surfaces generates a net torque of 701.95 N·m on the shaft. This high torque value demonstrates the turbine’s ability to generate significant force even from low-head water sources. Consequently, this hydraulic torque drives the screw to a steady rotational velocity of 2.023 rad/s, which converts to approximately 19.32 RPM. By combining these two values, we calculate the mechanical power output to be 1420 Watts (1.42 kW). This result is vital for the designer because it validates the blade geometry and inclination angle. It confirms that the current design successfully harnesses the gravitational force of the water to produce the expected power, ensuring the turbine is both mechanically safe and commercially viable for electricity generation.

| Parameter | Value | Unit | Converted Value |

| Torque | 701.95 | N·m | – |

| Rotational Velocity | 2.023 | rad/s | 19.32 RPM |

| Mechanical Power Output | 1420 | W | 1.42 kW |

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€155 Original price was: €155.€135Current price is: €135.

€220 Original price was: €220.€125Current price is: €125.

€145 Original price was: €145.€115Current price is: €115.

€195 Original price was: €195.€150Current price is: €150.

€210 Original price was: €210.€155Current price is: €155.

€245 Original price was: €245.€199Current price is: €199.

Reviews

There are no reviews yet.