Kelvin-Helmholtz Instability CFD: Analysis of Shear Layer Mixing Using ANSYS Fluent

Kelvin-Helmholtz Instability CFD: Analysis of Shear Layer Mixing Using ANSYS Fluent

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€65

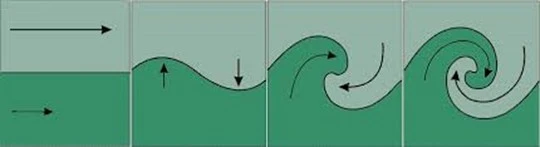

The Kelvin-Helmholtz Instability CFD study is a classic problem in fluid mechanics. This phenomenon happens when two fluids flow next to each other at different speeds. The difference in velocity creates a “shear” force at the interface. In nature, we see this in clouds or ocean waves. In engineering, understanding Kelvin-Helmholtz Instability ANSYS Fluent simulations is vital for designing efficient mixers, fuel injectors, and understanding atmospheric flows.

By performing a Kelvin-Helmholtz Instability CFD simulation, engineers can predict how quickly two fluids will mix. If the instability grows fast, mixing is good. If it stays smooth, mixing is poor. This report uses Kelvin-Helmholtz Instability Fluent tools to model the transition from a flat interface to complex rolling vortices. We use the Volume of Fluid (VOF) method to track the distinct boundary between the layers. This multiphase CFD simulation helps manufacturers optimize equipment where precise mixing is required, such as in chemical reactors or combustion chambers. For more examples of mixing and interfacial flows, please explore our Multiphase tutorials: https://cfdland.com/product-category/module/multiphase-cfd-simulation/

Figure 1: A conceptual diagram illustrating the Kelvin-Helmholtz Instability phenomenon where velocity shear creates waves.

Simulation Process: VOF Method and Inviscid Flow Setup in Fluent

The simulation process for this Kelvin-Helmholtz Instability CFD analysis started with a 2D rectangular domain. To capture the tiny waves accurately, we created a very fine, structured mesh. The grid consists of 484,832 quad cells. Using quad cells is essential for this type of Kelvin-Helmholtz Instability ANSYS Fluent study because they are aligned with the flow direction, which reduces numerical errors and keeps the interface sharp.

Inside the software, we used the Volume of Fluid (VOF) model. This is the standard method for tracking the exact position of the interface between two fluids. We set up the physics as Inviscid flow. This means we purposefully ignored viscosity (friction) to focus purely on the shear forces. This assumption makes the Kelvin-Helmholtz Instability Fluent calculation faster and isolates the primary cause of the instability. We used a Transient solver (time-dependent) to watch the instability grow from a small perturbation into large structures over time. This setup allows the multiphase CFD simulation to capture the exact moment the flow becomes unstable.

Post-processing: Vortex Roll-Up and Interface Evolution Analysis

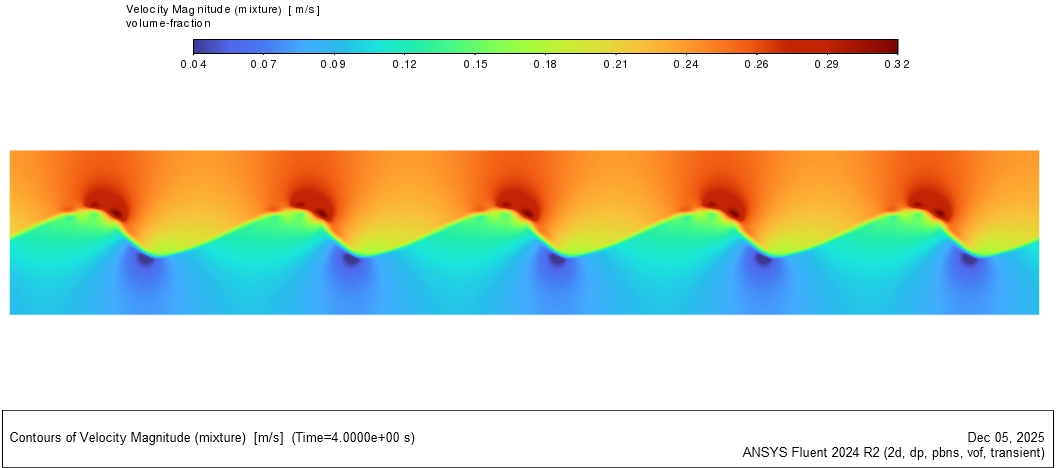

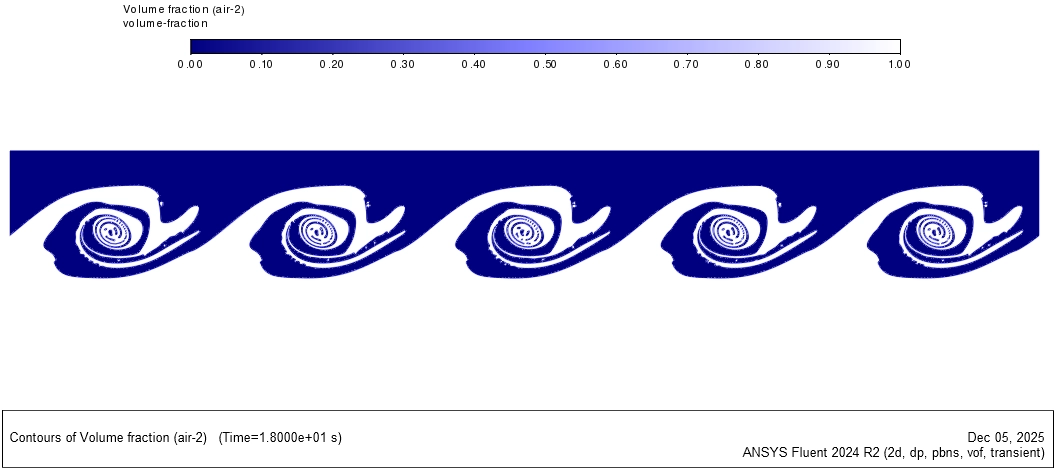

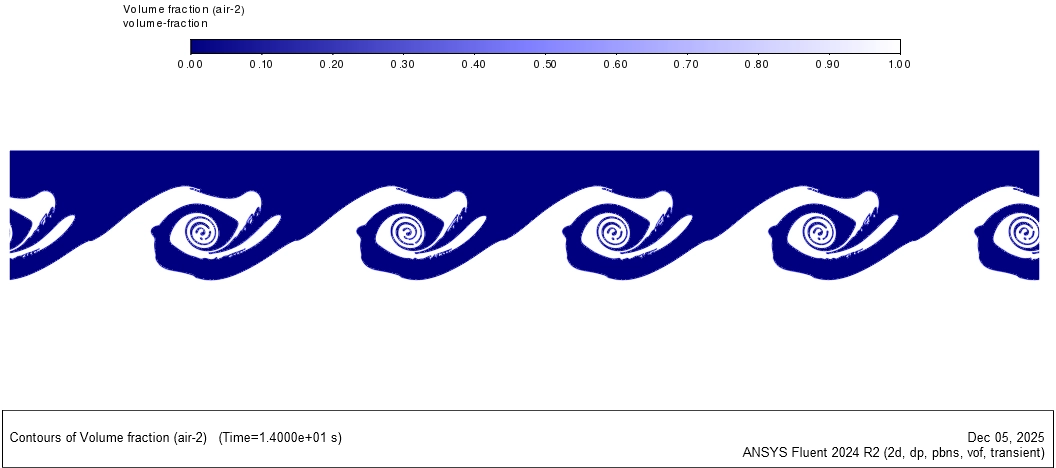

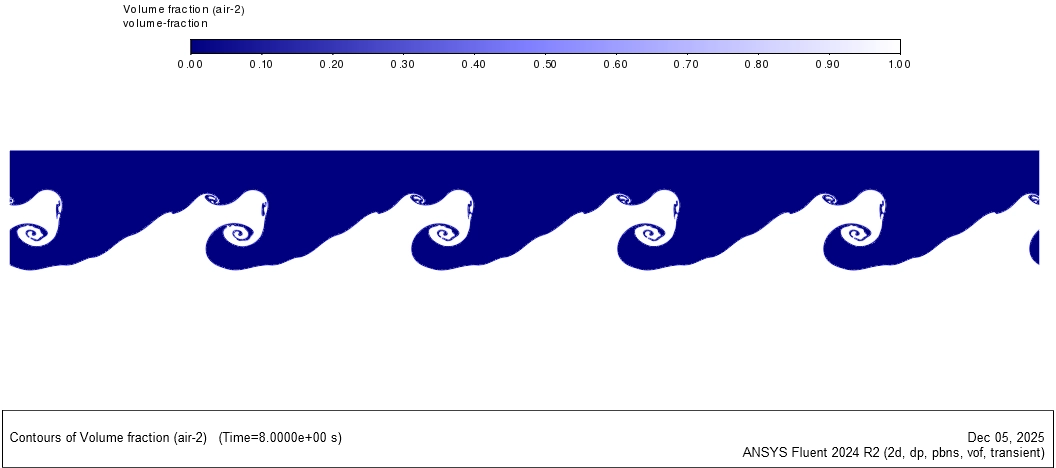

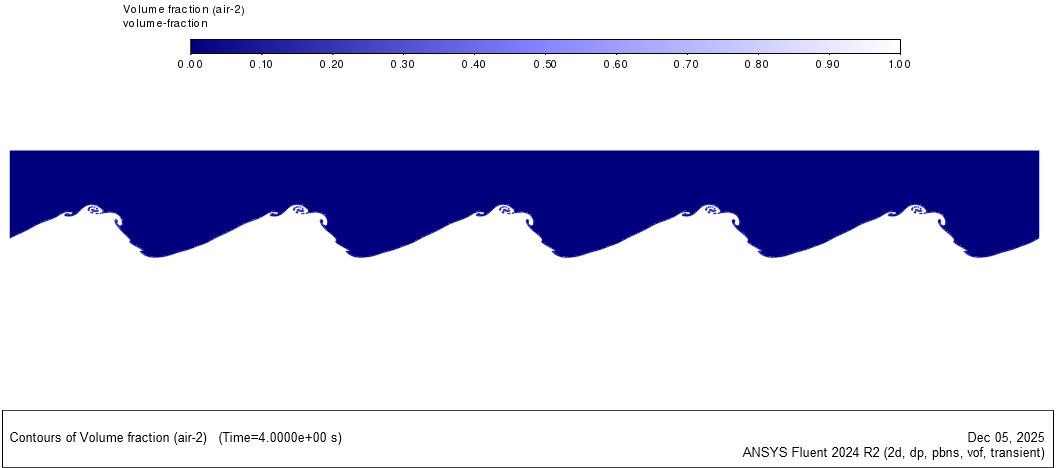

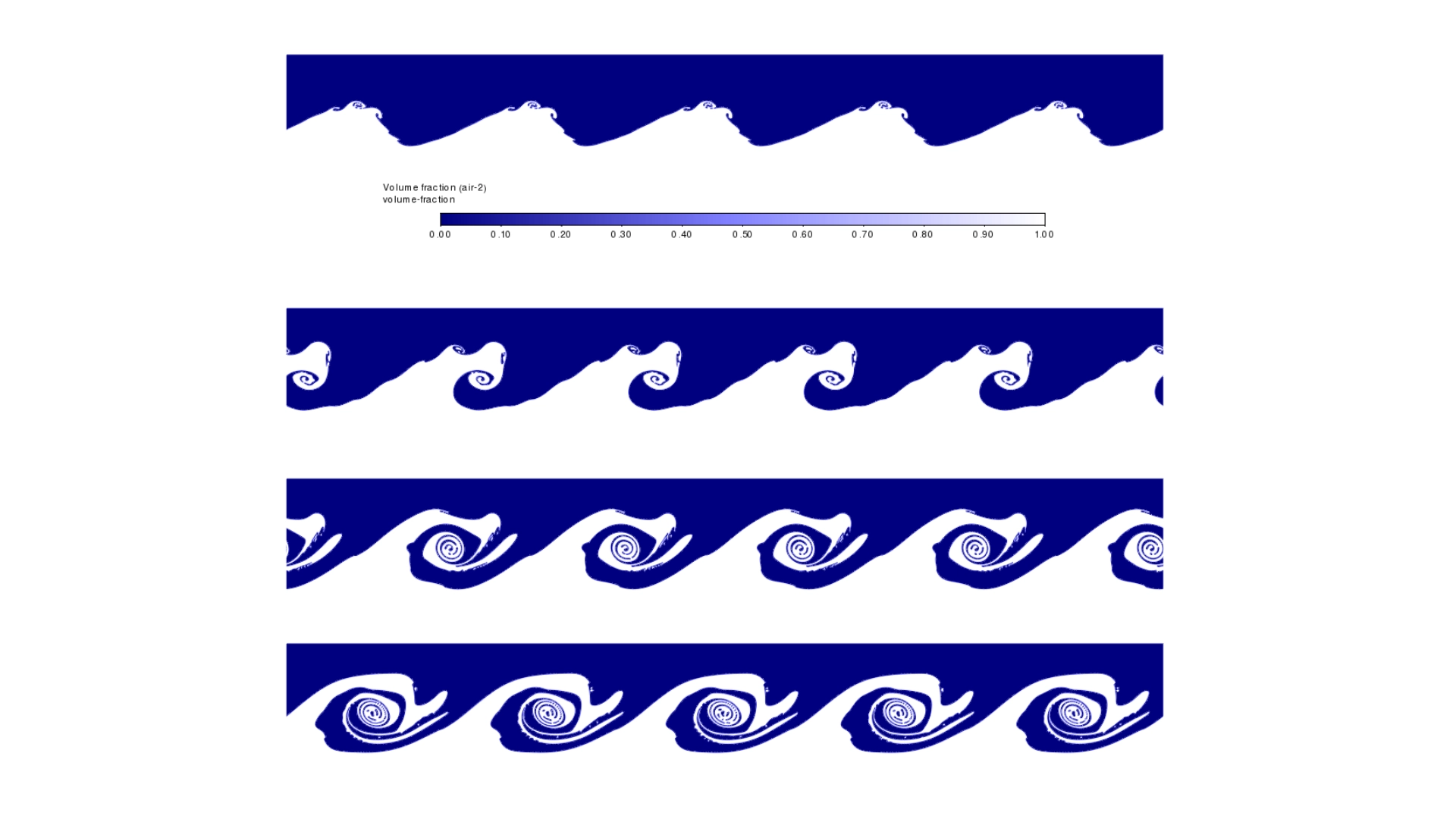

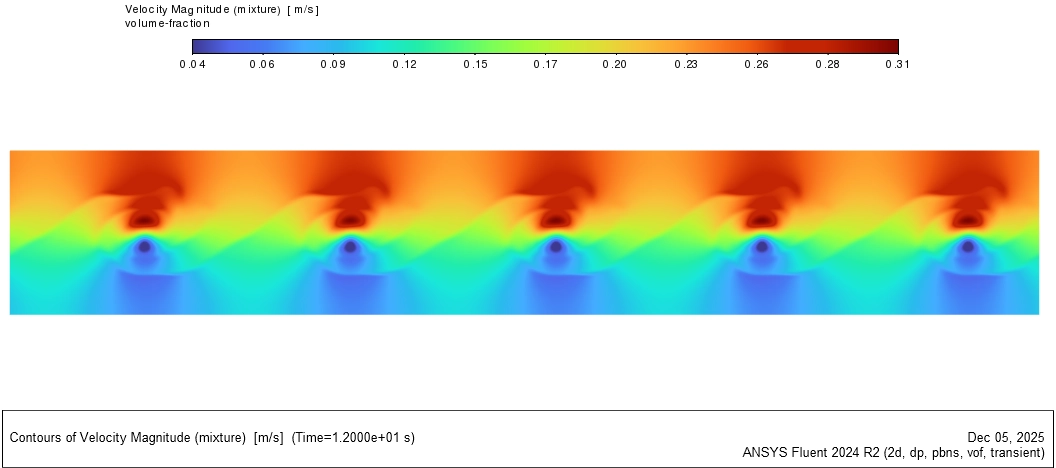

The post-processing analysis provides a clear timeline of how mixing occurs. We must examine the Volume Fraction contours in Figure 2 to understand the physics. The images show the interface evolution at four distinct moments. In the top image (early time), the boundary between the blue fluid (fast top layer) and the white fluid (slow bottom layer) is almost flat. We only see tiny, rhythmic bumps. This proves that the Kelvin-Helmholtz Instability CFD simulation has successfully triggered the initial disturbance. As we move to the second and third images, these bumps grow rapidly into tall waves. This confirms the linear growth phase of the instability. The velocity difference amplifies the waves because the fast fluid pushes the crests forward while the slow fluid drags the troughs back.

Figure 2: Volume Fraction contours at four sequential time steps from the ANSYS Fluent simulation, visualizing the evolution from linear waves to fully rolled-up vortices.

The most critical engineering achievement is seen in the bottom image. Here, the waves have curled over completely to form tight, spiraling vortices. This is the classic “cat’s eye” pattern. For a mixer designer, this moment is crucial. It represents the transition to turbulent mixing. The simulation proves that the shear force alone is strong enough to roll the fluids together. The interface length has increased significantly, which means the contact area between the two fluids is maximized. By analyzing these Kelvin-Helmholtz Instability Fluent results, a manufacturer can determine exactly how long their mixing channel needs to be. If the channel is too short, the vortices won’t form, and the product will be poor. This analysis confirms that the shear velocity is the main control knob for efficient mixing performance.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€145 Original price was: €145.€65Current price is: €65.

€310 Original price was: €310.€175Current price is: €175.

€220 Original price was: €220.€135Current price is: €135.

€175 Original price was: €175.€115Current price is: €115.

€195 Original price was: €195.€150Current price is: €150.

€210 Original price was: €210.€155Current price is: €155.

Reviews

There are no reviews yet.