Transient Two-way FSI CFD Simulation of a Flexible Seal in a Pipe using Structure Module

Transient Two-way FSI CFD Simulation of a Flexible Seal in a Pipe using Structure Module

- Upon ordering this product, you will be provided with a geometry file, a mesh file, and an in-depth Training Video that offers a step-by-step training on the simulation process.

- For any more inquiries regarding the product, please do not hesitate to reach out to us at info@CFDLAND.com or through our online support assistant.

€140

A Two-way FSI CFD simulation is essential for designing and understanding any system where a flexible part interacts with a moving fluid. A perfect example is a flexible rubber seal inside a pipe. This is a classic Fluid-structure Interaction CFD problem. When fluid flows through the pipe, it pushes and pulls on the seal, causing it to bend and deform. But this is only half the story. As the seal deforms, it changes the shape of the pipe, which in turn changes the speed and pressure of the fluid. This creates a continuous feedback loop where the fluid affects the structure, and the structure’s movement affects the fluid. This is what we call Two-way FSI.

This report details a transient Two-way FSI Fluent simulation of a flexible seal. “Transient” means the simulation is run over time, which is critical because a seal doesn’t deform instantly; it responds dynamically to changes in pressure. To solve this complex problem, a two-way Fluid–Structure Interaction (FSI) model was developed entirely within ANSYS Fluent . A special technique inside Fluent, sometimes called Intrinsic FSI, allows these two solvers to “talk” to each other at every single time step. Fluent tells the structure ansys model about the fluid forces, and the structure model tells Fluent how it has moved. This detailed conversation allows engineers to see exactly how the seal will behave in the real world, helping them predict if it will seal properly, if it will vibrate, or if the stresses inside it are too high, ensuring the final product is both safe and reliable. For more FSI tutorials, check out here.

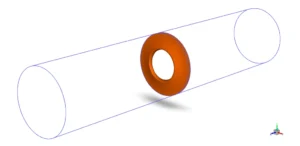

Figure 1: A photograph of a typical flexible rubber seal used in pipe systems, the subject of this Fluid-Structure Interaction CFD study.

Simulation Process: Fluent for Intrinsic FSI

The transient FSI simulation begins with configuring the Structure module in Ansys for linear elasticity analysis of the flexible seal, which assumes that the seal material follows Hooke’s law where stress is directly proportional to strain and the seal returns to its original shape when forces are removed – this linear elasticity assumption is valid for most rubber and polymer seals under normal operating conditions where deformations remain small (typically less than 10-20% strain). These determine how the seal responds to fluid pressure and forces during the 2-way FSI coupling.

The CFD portion of the 2-way FSI simulation uses Ansys Fluent with airflow at 10 m/s velocity to represent the fluid conditions that will interact with the flexible seal – this airflow velocity is typical for many industrial applications including HVAC systems, pneumatic controls, and ventilation pipes where seals must maintain performance under moderate flow conditions. The dynamic mesh capability in Fluent is essential for FSI analysis because as the flexible seal deforms due to fluid forces, the fluid domain shape changes and the CFD mesh must adapt to maintain solution accuracy. The smoothing method for dynamic mesh is configured to use a linearly elastic solid model, which treats the CFD mesh like a flexible elastic material that can stretch and compress as boundary nodes move due to seal.

Figure 2: The geometry schematic used in the ANSYS simulation, showing the fluid domain (the pipe) and the solid domain (the flexible seal).

Post-processing: Engineering Investigation of Coupled Physics

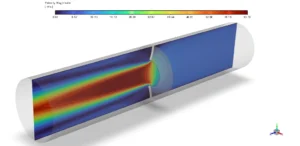

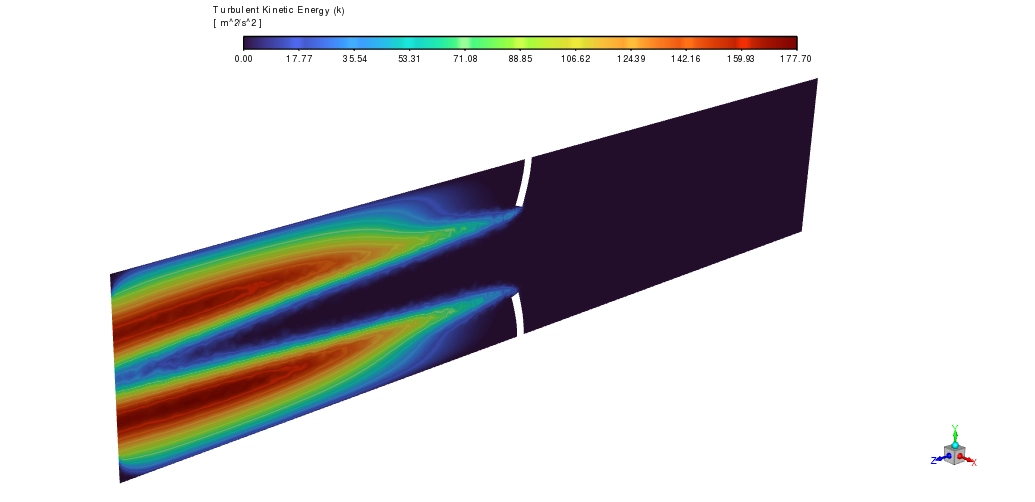

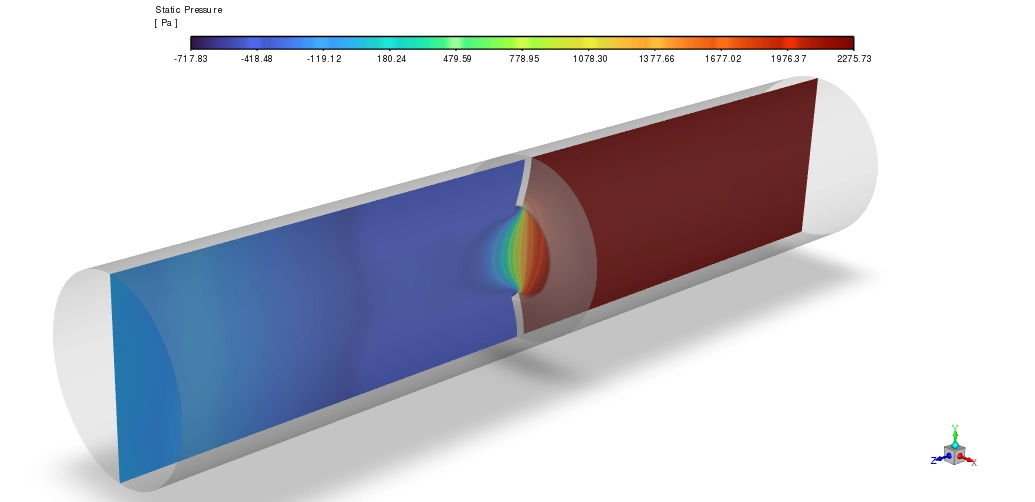

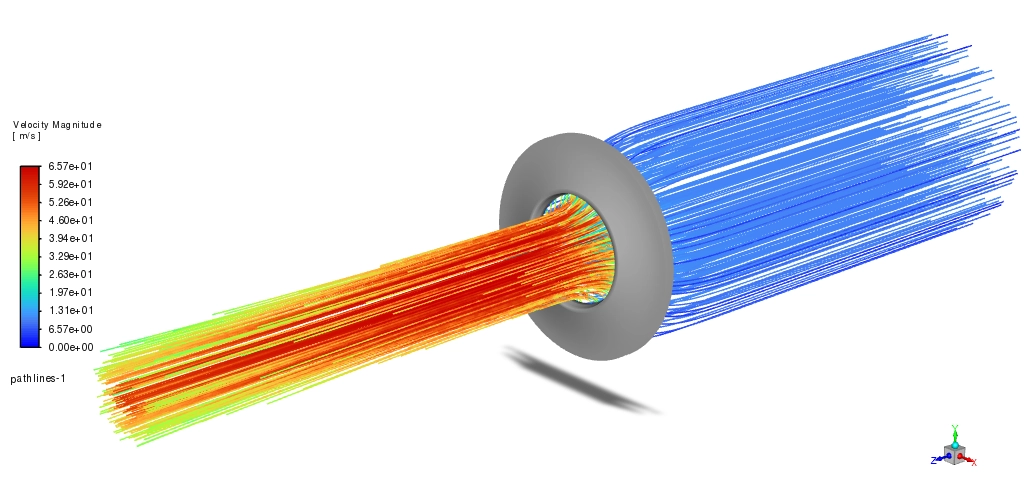

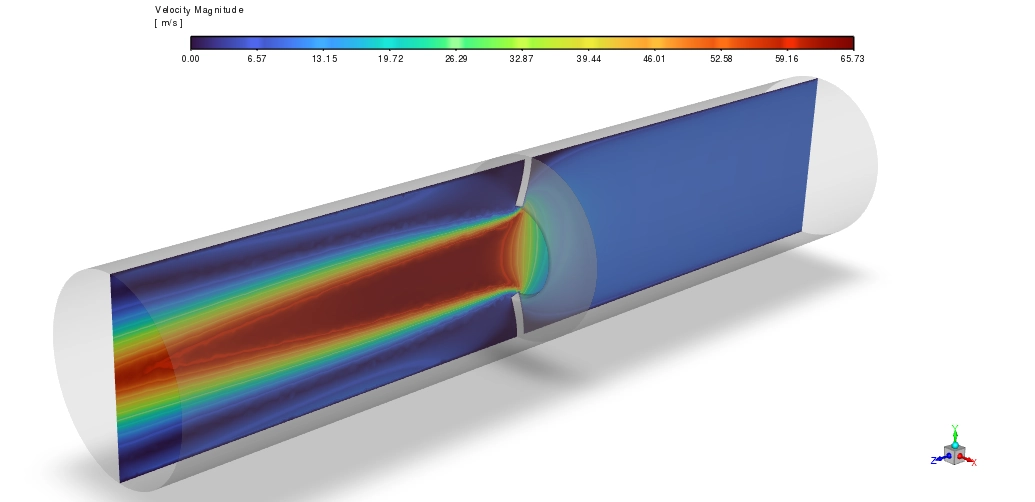

The simulation results allow us to conduct a full engineering investigation into the dynamic “conversation” between the airflow and the flexible seal. We will examine the cause (the fluid’s action), the effect (the seal’s reaction), and the critical feedback loop that defines this two-way FSI problem. The investigation begins with the fluid. The velocity contour in Figure 4 shows what the air is doing. While the air enters the pipe at 10 m/s, it is forced to squeeze through the narrow gap created by the deformed seal. Just like putting your thumb over the end of a garden hose, this restriction causes the air to speed up dramatically. The contour shows that the velocity in this gap reaches a maximum of 65.73 m/s. This high-speed flow creates a complex pressure field on the seal’s surface. The upstream face of the seal is hit by the incoming flow, creating a positive pressure that pushes it. At the same time, the very fast flow in the gap creates a low-pressure zone (due to the Bernoulli effect) that pulls and sucks on the seal. It is this combination of pushing and pulling forces that represents the fluid’s “action” on the structure.

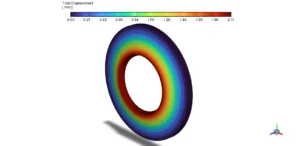

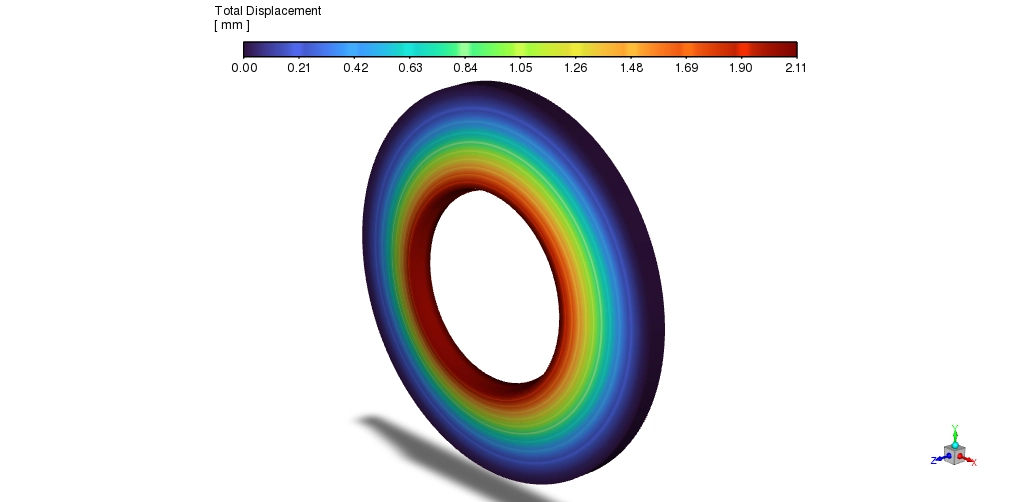

Now we investigate the seal’s reaction to these fluid forces. The total displacement contour in Figure 5 provides clear evidence of the effect. The seal has bent inward, with the inner edge moving the most. The simulation precisely quantifies this deformation, showing a maximum displacement of 2.11 mm at the tip. The displacement gradually reduces to zero at the outer edge, where the seal is held in place by the pipe wall. This deformed shape is the direct physical consequence of the pressure load applied by the fluid.

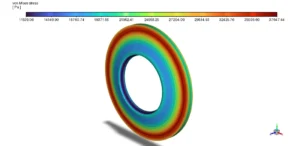

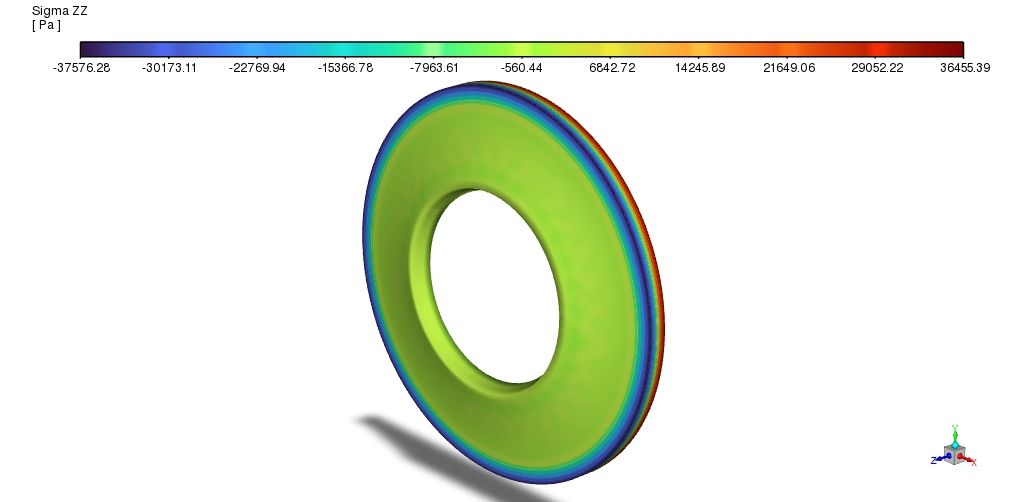

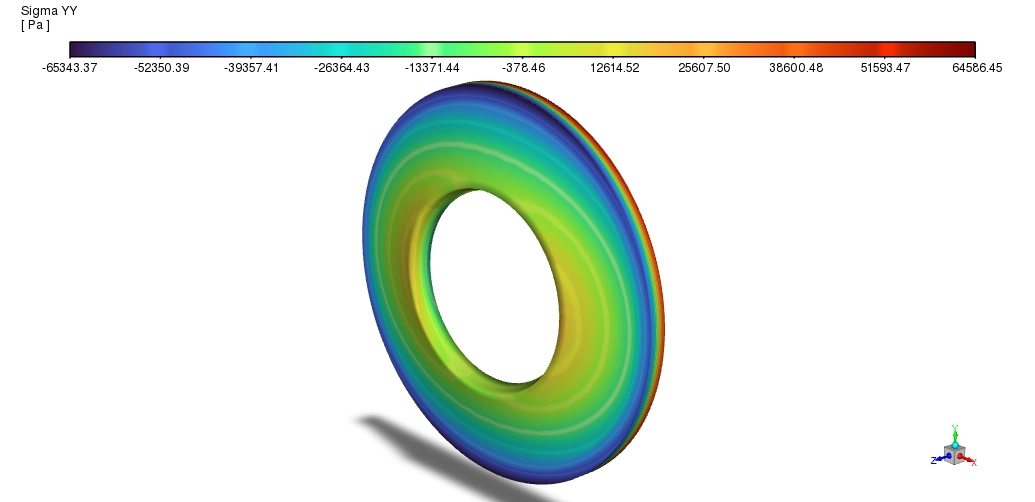

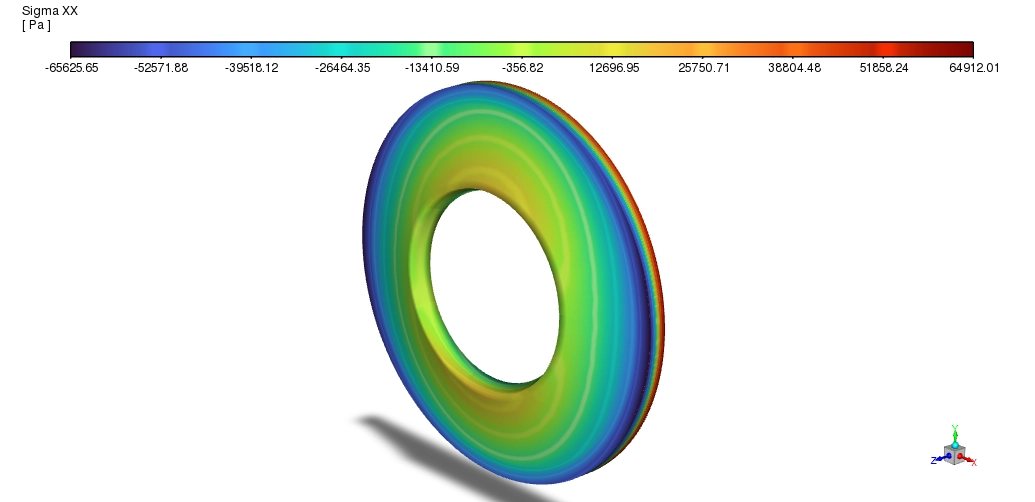

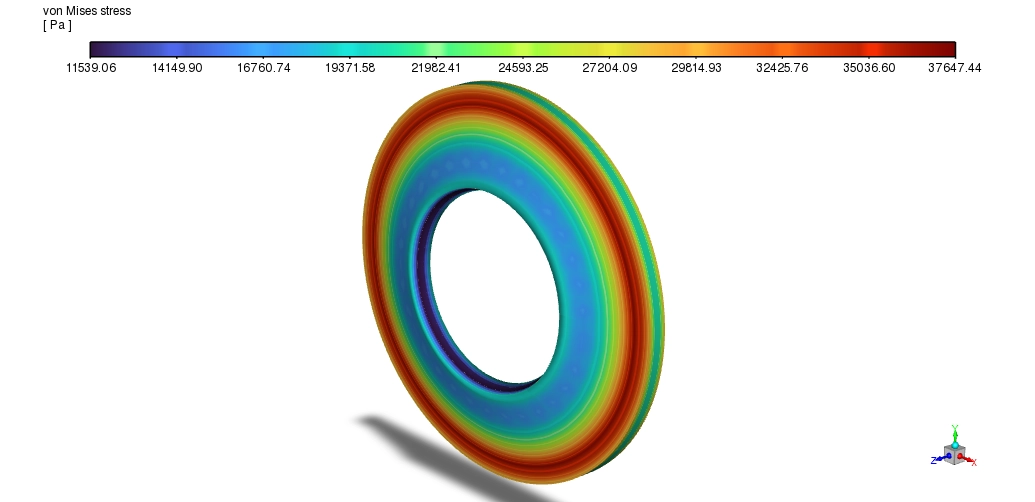

Figure 3: on Mises stress distribution in the flexible seal from transient 2-way FSI simulation using Structure Fluent Module showing stress concentrations

This bending also creates internal stress inside the seal material. The von Mises stress contour in Figure 3 shows us this internal reaction. The stress is highest (red region, up to 37,647 Pa) right at the inner corner where the bending is most severe. The stress is lowest at the supported outer edge. From an engineering viewpoint, this is the most critical safety check. The simulation shows that the maximum stress is 0.038 MPa, which is extremely low and well within the safe operating limit for any typical seal material. This confirms the seal will not fail under these conditions.

Figure 4: Velocity magnitude contour from CFD analysis in Fluent displaying airflow acceleration around the deformed flexible seal, with velocities range

Figure 5: Total displacement contour showing flexible seal deformation from ANSYS Structure module with linear elasticity material

The most important part of this investigation is understanding the “two-way” part of the interaction. The story does not end with the seal deforming. The 2.11 mm deformation is the “reaction,” but this reaction changes the original “action.” By bending inward, the seal is what causes the gap to become narrow. It is this structural deformation that forces the air to accelerate to 65.73 m/s. This is the feedback from the structure back to the fluid. The fluid pushes the seal, causing it to deform. The deformation changes the flow path, causing the fluid to speed up. The faster fluid changes the pressure, which in turn affects the seal’s deformation. The most important achievement of this simulation is the successful capture of this complete, dynamic, and fully coupled feedback loop.

We pride ourselves on presenting unique products at CFDLAND. We stand out for our scientific rigor and validity. Our products are not based on guesswork or theoretical assumptions like many others. Instead, most of our products are validated using experimental or numerical data from valued scientific journals. Even if direct validation isn’t possible, we build our models and assumptions on the latest research, typically using reference articles to approximate reality.

Yes, we’ll be here . If you have trouble loading files, having technical problems, or have any questions about how to use our products, our technical support team is here to help.

You can load geometry and mesh files, as well as case and data files, using any version of ANSYS Fluent.

€145 Original price was: €145.€115Current price is: €115.

€160 Original price was: €160.€135Current price is: €135.

€145 Original price was: €145.€125Current price is: €125.

€140 Original price was: €140.€85Current price is: €85.

€265 Original price was: €265.€135Current price is: €135.

€240 Original price was: €240.€135Current price is: €135.

Reviews

There are no reviews yet.